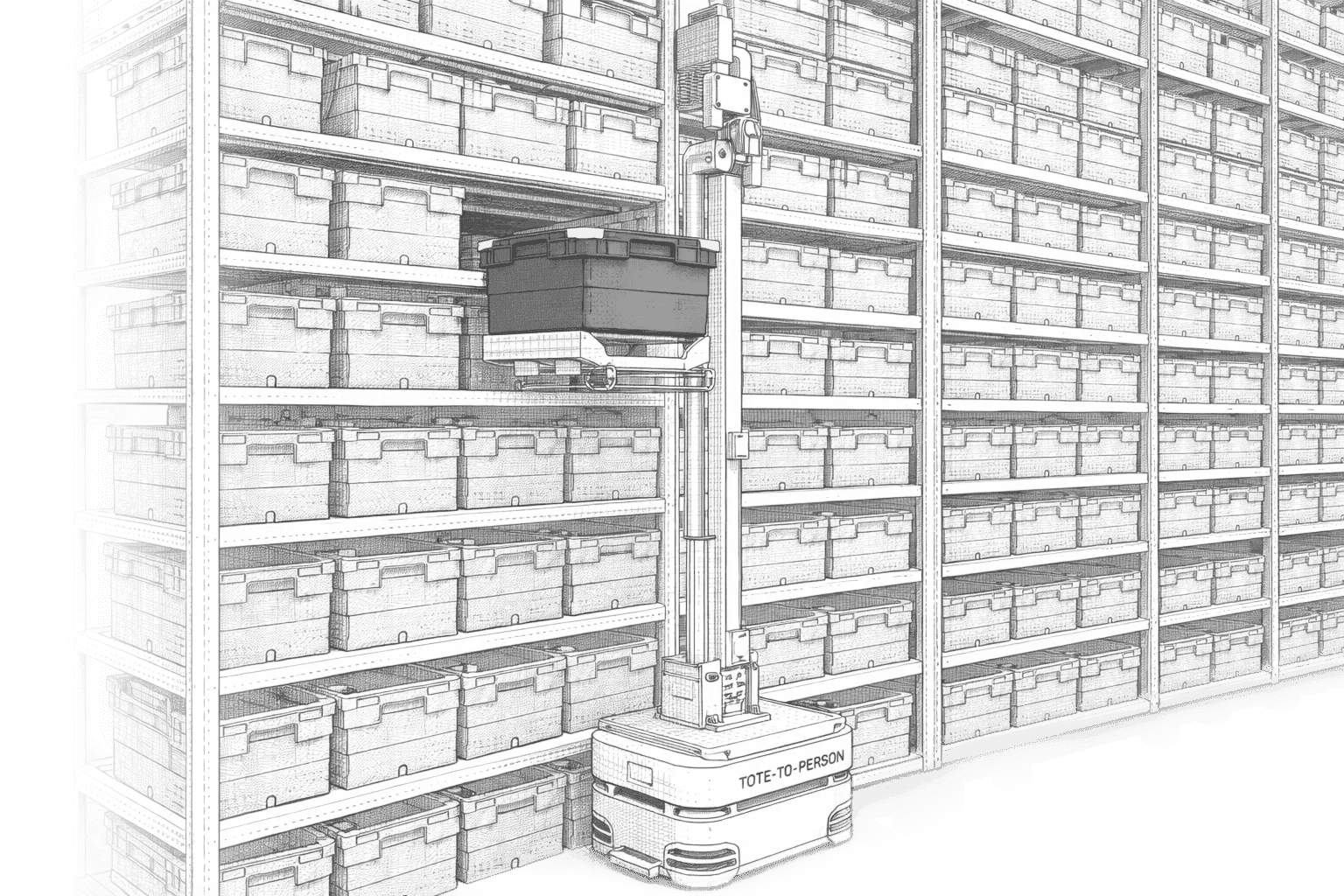

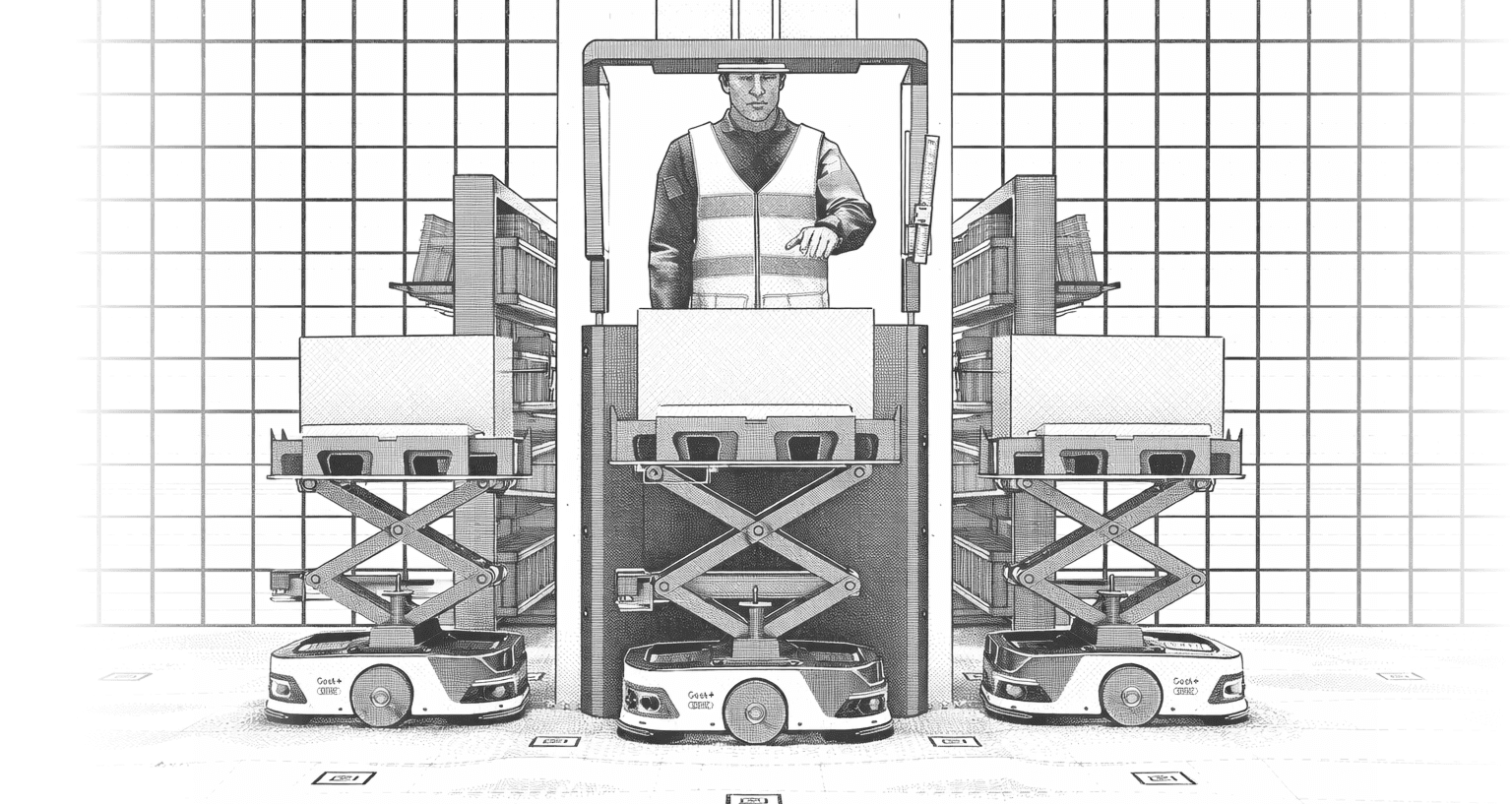

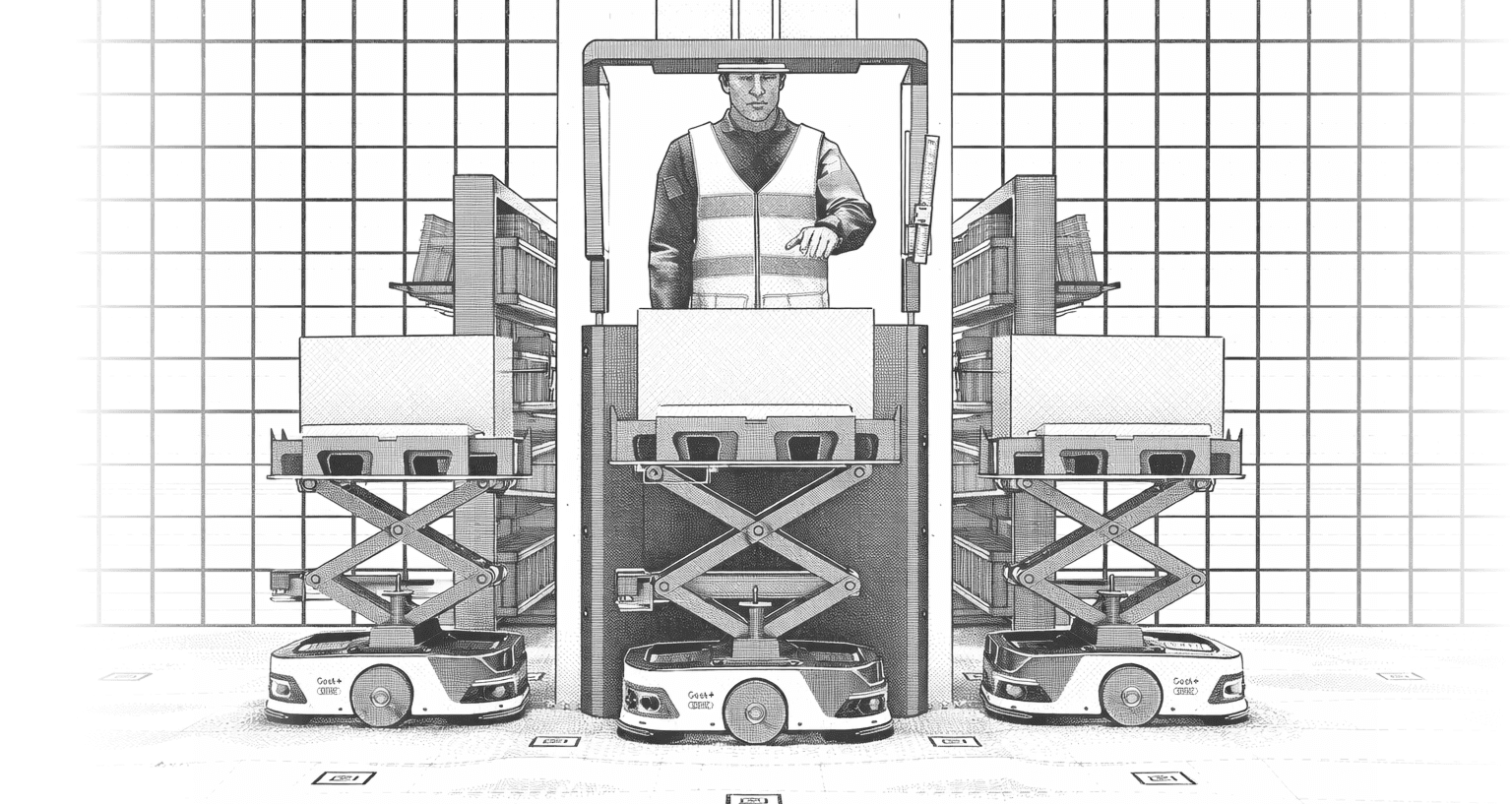

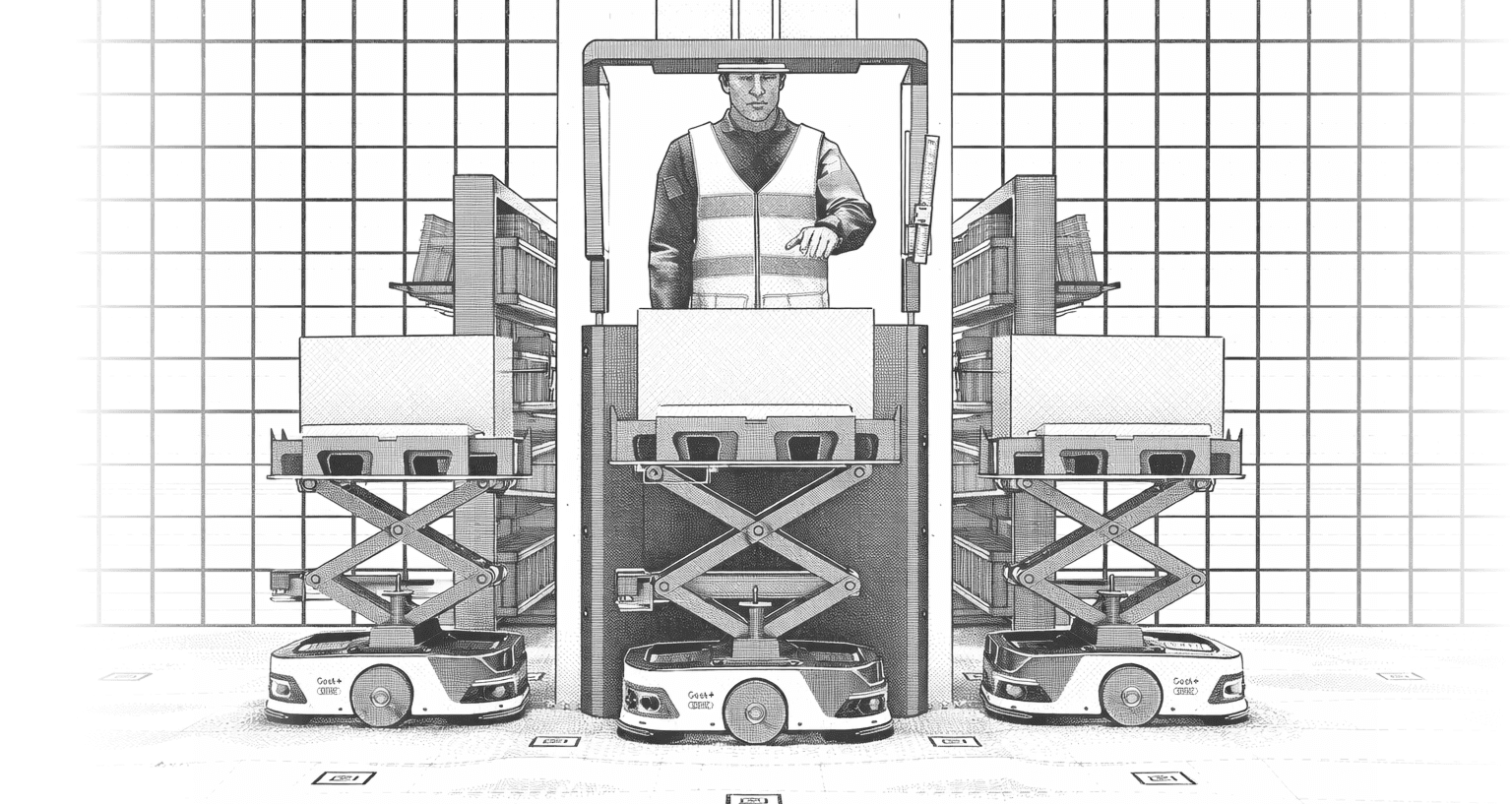

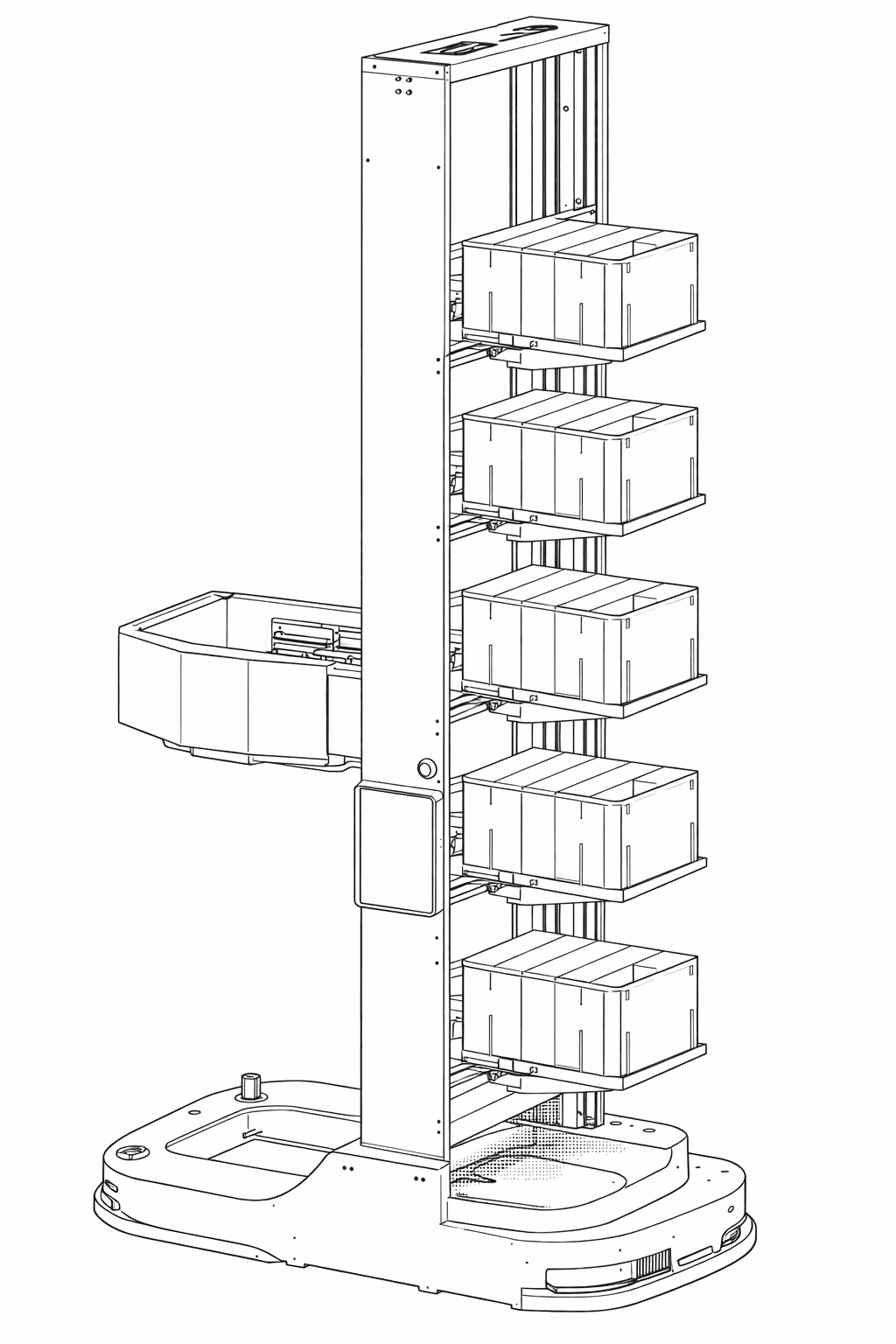

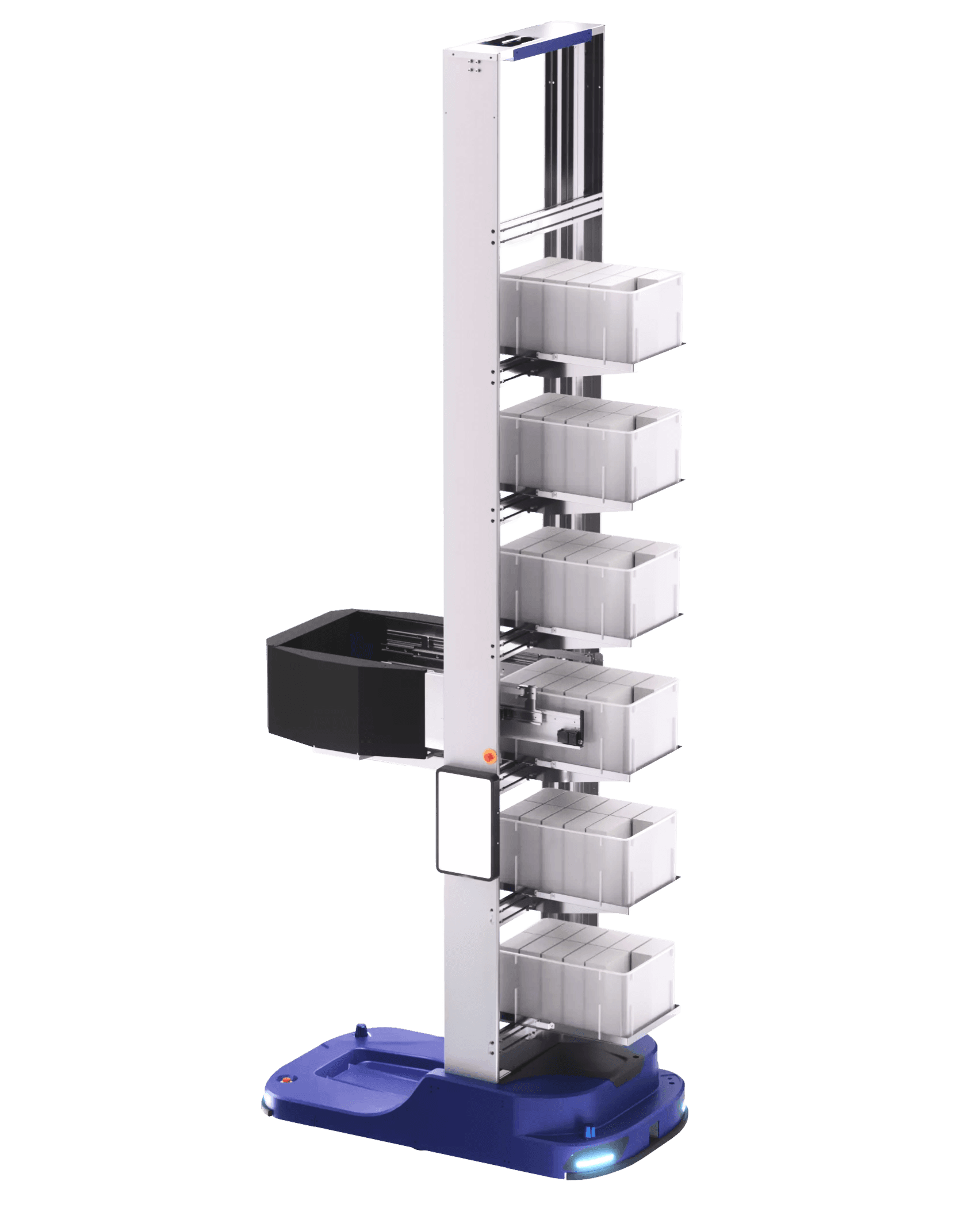

Tote-to-Person Picking

Shuttle robots designed for vertical storage and rapid tote access, delivering high picking throughput.

Obstacles

Challenges in high-SKU warehouse picking

Growing SKU complexity

Warehouses with thousands of SKUs lose picking efficiency as operators spend time searching for items, increasing errors and cycle times.

Growing SKU complexity

Warehouses with thousands of SKUs lose picking efficiency as operators spend time searching for items, increasing errors and cycle times.

Growing SKU complexity

Warehouses with thousands of SKUs lose picking efficiency as operators spend time searching for items, increasing errors and cycle times.

Manual picking constraints

Manual picking in multi-level storage increases travel time and safety risks, slowing order fulfillment and limiting throughput.

Manual picking constraints

Manual picking in multi-level storage increases travel time and safety risks, slowing order fulfillment and limiting throughput.

Manual picking constraints

Manual picking in multi-level storage increases travel time and safety risks, slowing order fulfillment and limiting throughput.

Peak-order bottlenecks

Peak order volumes overwhelm manual picking, causing delays, backlogs, and missed fulfillment SLAs.

Peak-order bottlenecks

Peak order volumes overwhelm manual picking, causing delays, backlogs, and missed fulfillment SLAs.

Peak-order bottlenecks

Peak order volumes overwhelm manual picking, causing delays, backlogs, and missed fulfillment SLAs.

Limited storage density

Manual aisles and picking zones reduce usable storage space, causing warehouses to hit capacity limits early.

Limited storage density

Manual aisles and picking zones reduce usable storage space, causing warehouses to hit capacity limits early.

Limited storage density

Manual aisles and picking zones reduce usable storage space, causing warehouses to hit capacity limits early.

Labor-dependent performance

Picking speed and accuracy depend heavily on operator experience, while training and turnover reduce overall performance.

Labor-dependent performance

Picking speed and accuracy depend heavily on operator experience, while training and turnover reduce overall performance.

Labor-dependent performance

Picking speed and accuracy depend heavily on operator experience, while training and turnover reduce overall performance.

Returns and re-slotting friction

Returns, re-slotting, and frequent SKU changes disrupt picking locations and workflows, increasing mispicks and slowing fulfillment.

Returns and re-slotting friction

Returns, re-slotting, and frequent SKU changes disrupt picking locations and workflows, increasing mispicks and slowing fulfillment.

Returns and re-slotting friction

Returns, re-slotting, and frequent SKU changes disrupt picking locations and workflows, increasing mispicks and slowing fulfillment.

Solution

How Tote-to-Person solves these challenges

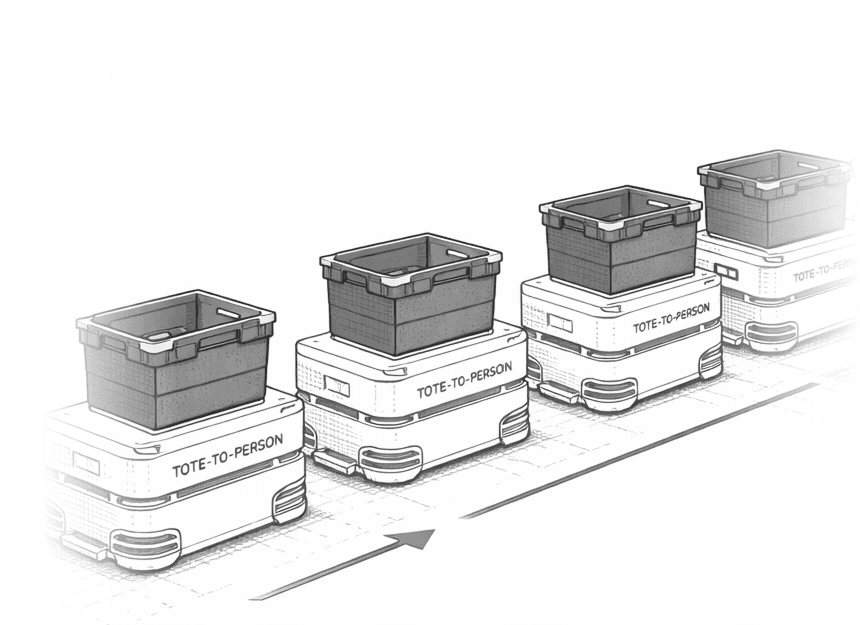

Stable throughput during peaks

Robots queue totes automatically, maintaining a continuous flow to picking stations even under extreme order bursts — keeping SLAs intact without extra labor.

Stable throughput during peaks

Robots queue totes automatically, maintaining a continuous flow to picking stations even under extreme order bursts — keeping SLAs intact without extra labor.

Stable throughput during peaks

Robots queue totes automatically, maintaining a continuous flow to picking stations even under extreme order bursts — keeping SLAs intact without extra labor.

Benefits

Tote-to-Person Picking advantages

Compatible with all item sizes

Improved efficiency

Optimised space usage

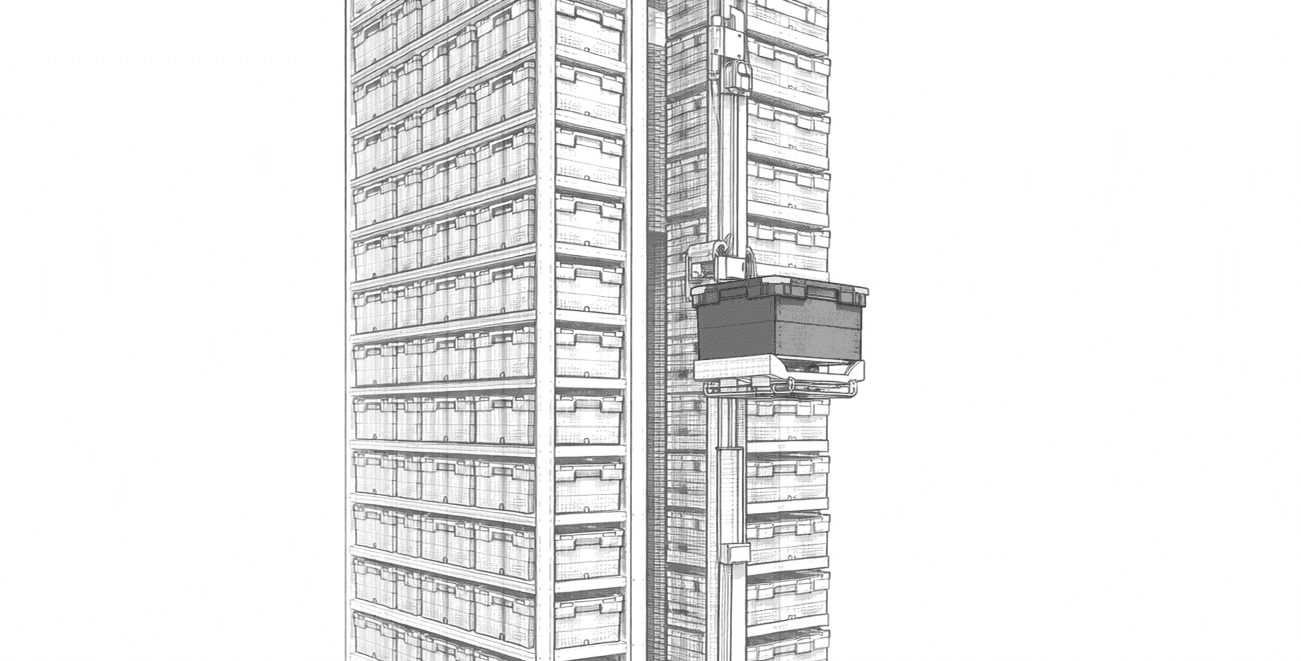

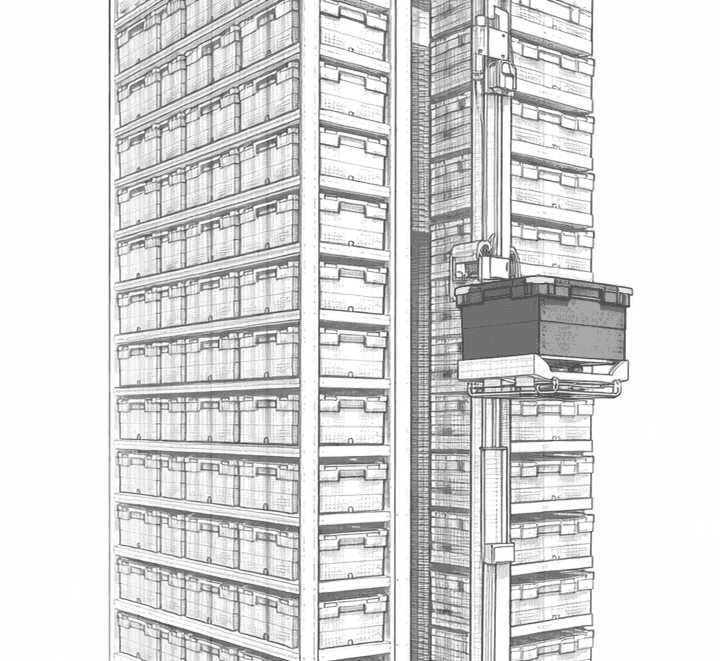

Picking height up to 10 meters

Up to 800 totes processed per hour per station

Cost-effective

Compatible with all item sizes

Improved efficiency

Optimised space usage

Picking height up to 10 meters

Up to 800 totes processed per hour per station

Cost-effective

Compatible with all item sizes

Improved efficiency

Optimised space usage

Picking height up to 10 meters

Up to 800 totes processed per hour per station

Cost-effective

Compatible with all item sizes

Improved efficiency

Optimised space usage

Picking height up to 10 meters

Up to 800 totes processed per hour per station

Cost-effective

Compatible with all item sizes

Improved efficiency

Optimised space usage

Picking height up to 10 meters

Up to 800 totes processed per hour per station

Cost-effective

Compatible with all item sizes

Improved efficiency

Optimised space usage

Picking height up to 10 meters

Up to 800 totes processed per hour per station

Cost-effective

Compatible with all item sizes

Improved efficiency

Optimised space usage

Picking height up to 10 meters

Up to 800 totes processed per hour per station

Cost-effective

Compatible with all item sizes

Improved efficiency

Optimised space usage

Picking height up to 10 meters

Up to 800 totes processed per hour per station

Cost-effective

Compatible with all item sizes

Improved efficiency

Optimised space usage

Picking height up to 10 meters

Up to 800 totes processed per hour per station

Cost-effective

Compatible with all item sizes

Improved efficiency

Optimised space usage

Picking height up to 10 meters

Up to 800 totes processed per hour per station

Cost-effective

Compatible with all item sizes

Improved efficiency

Optimised space usage

Picking height up to 10 meters

Up to 800 totes processed per hour per station

Cost-effective

Compatible with all item sizes

Improved efficiency

Optimised space usage

Picking height up to 10 meters

Up to 800 totes processed per hour per station

Cost-effective

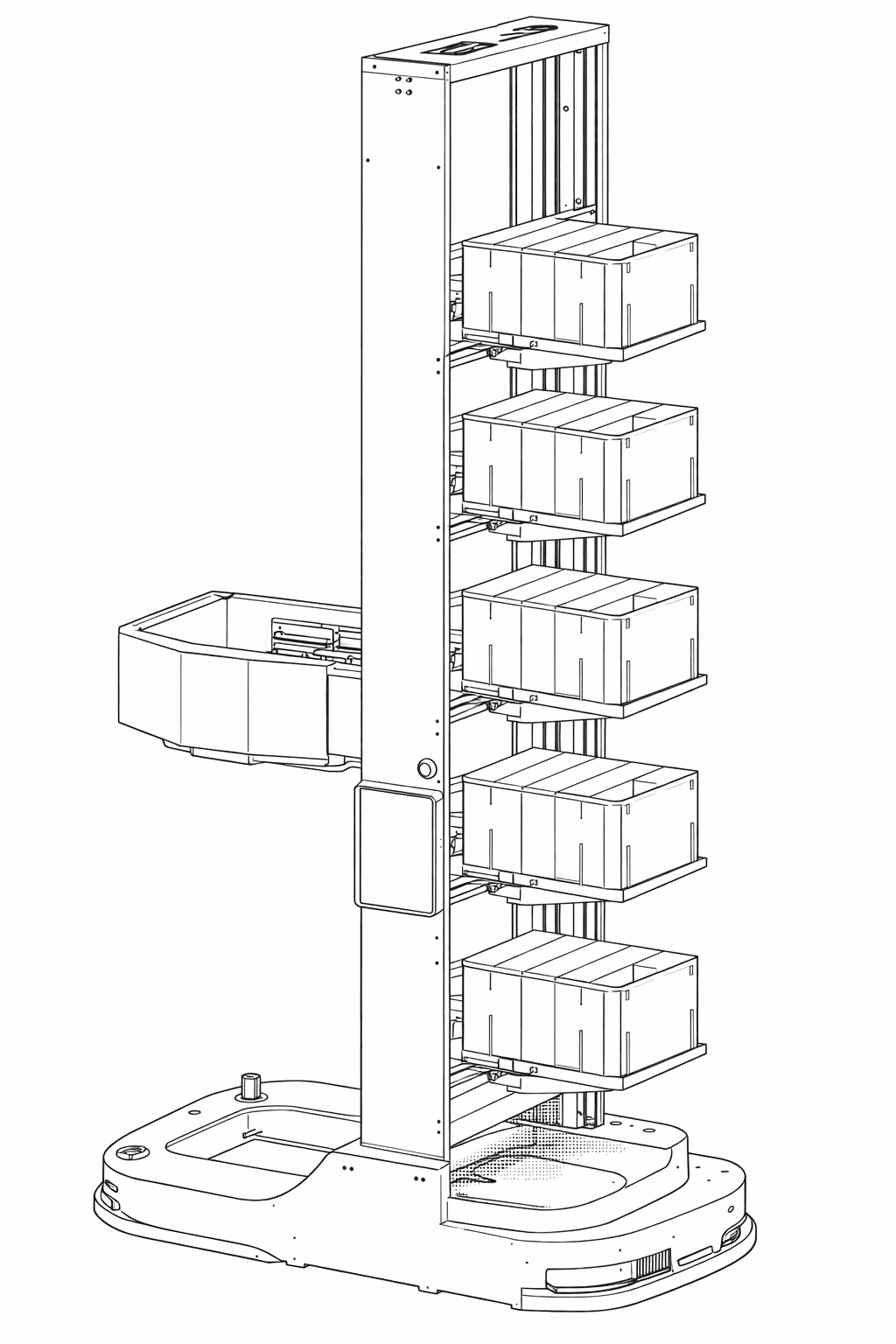

Robot portfolio

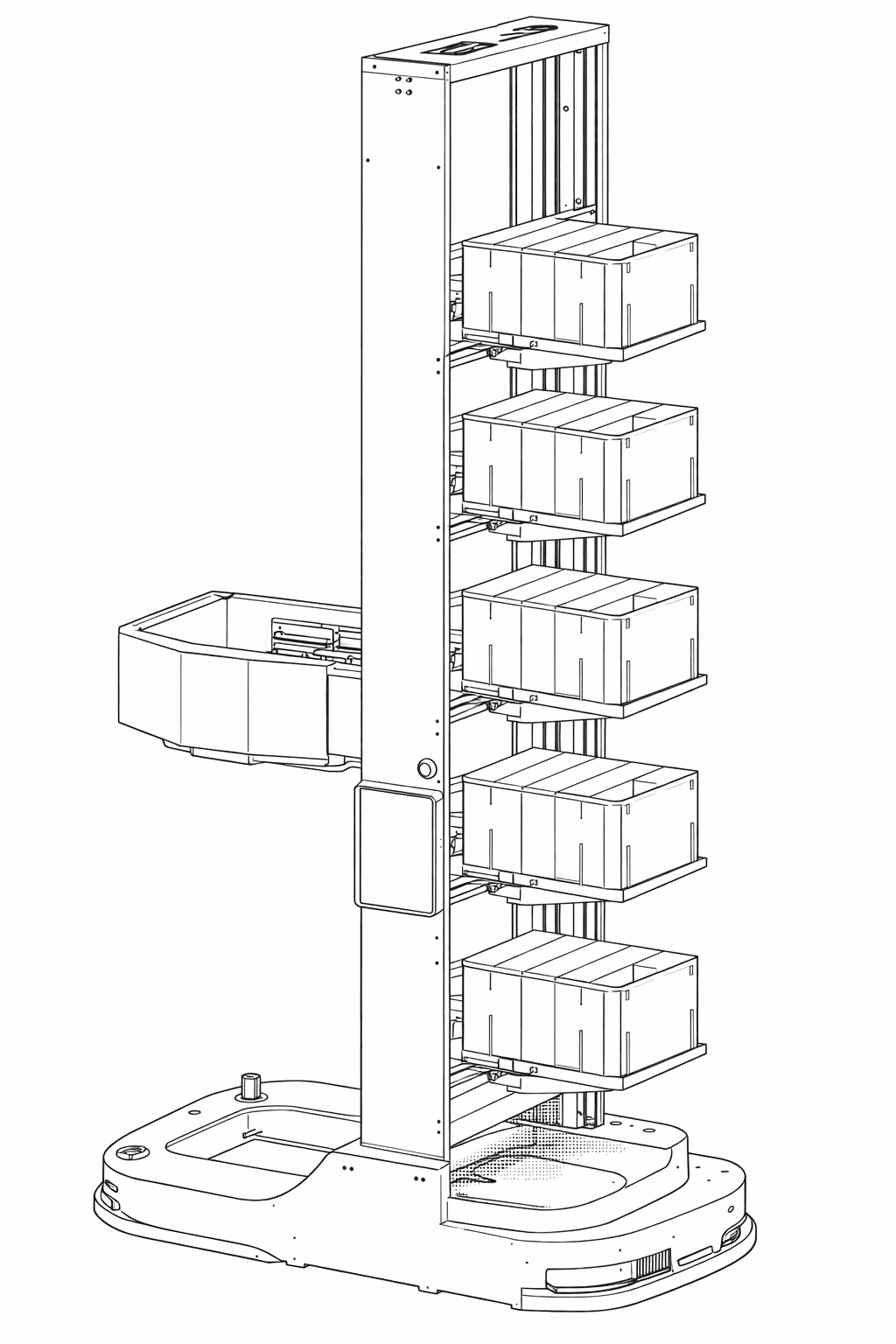

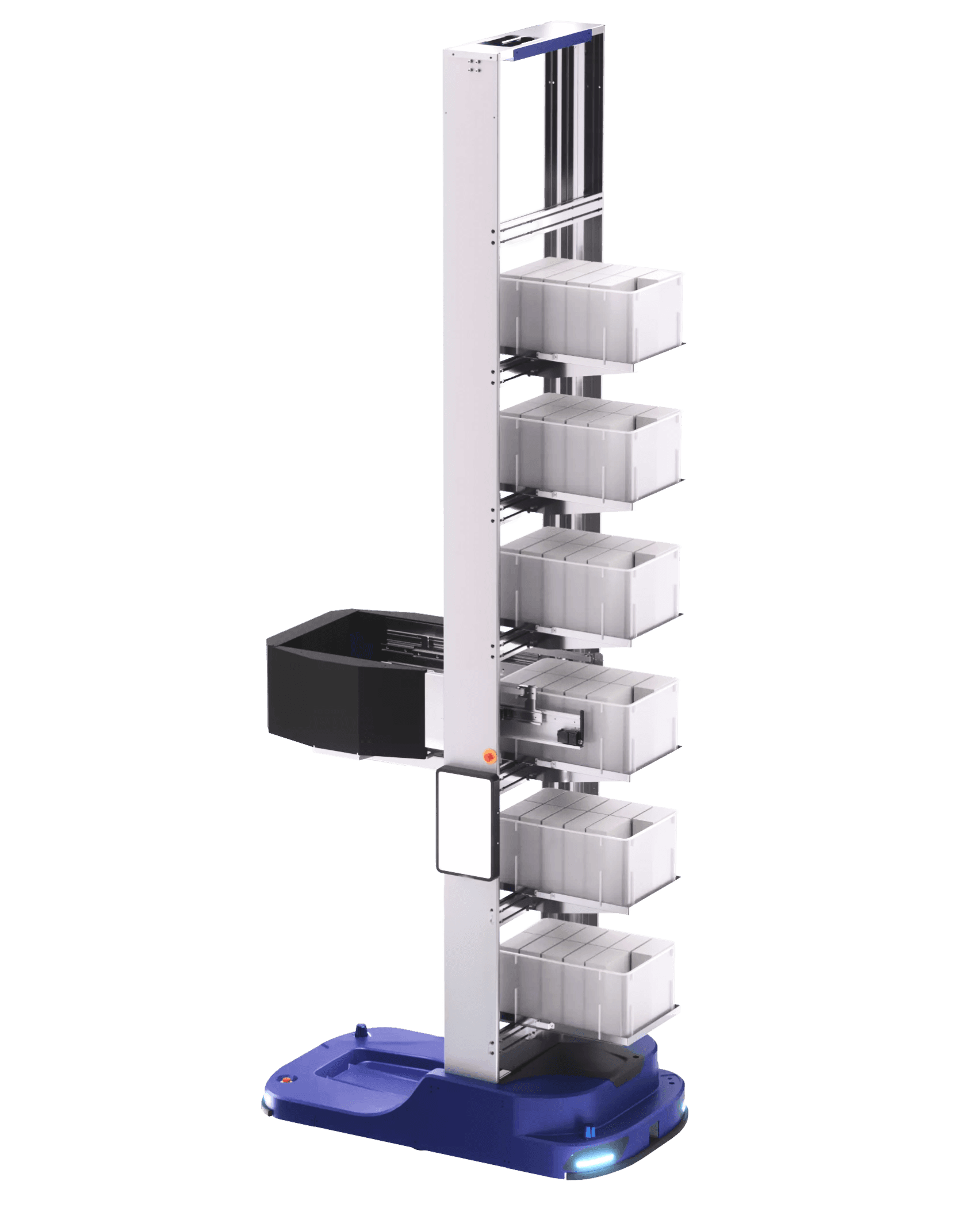

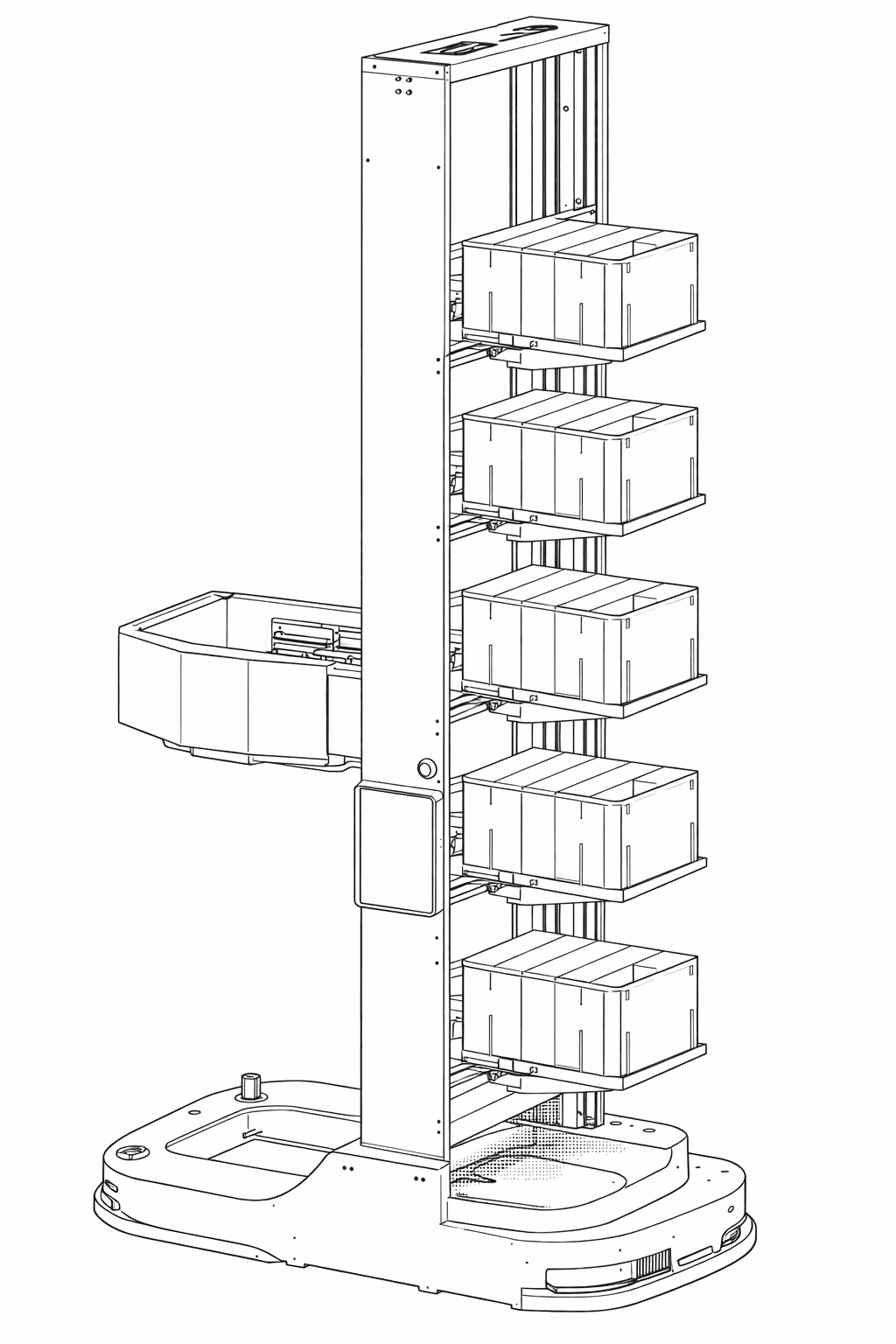

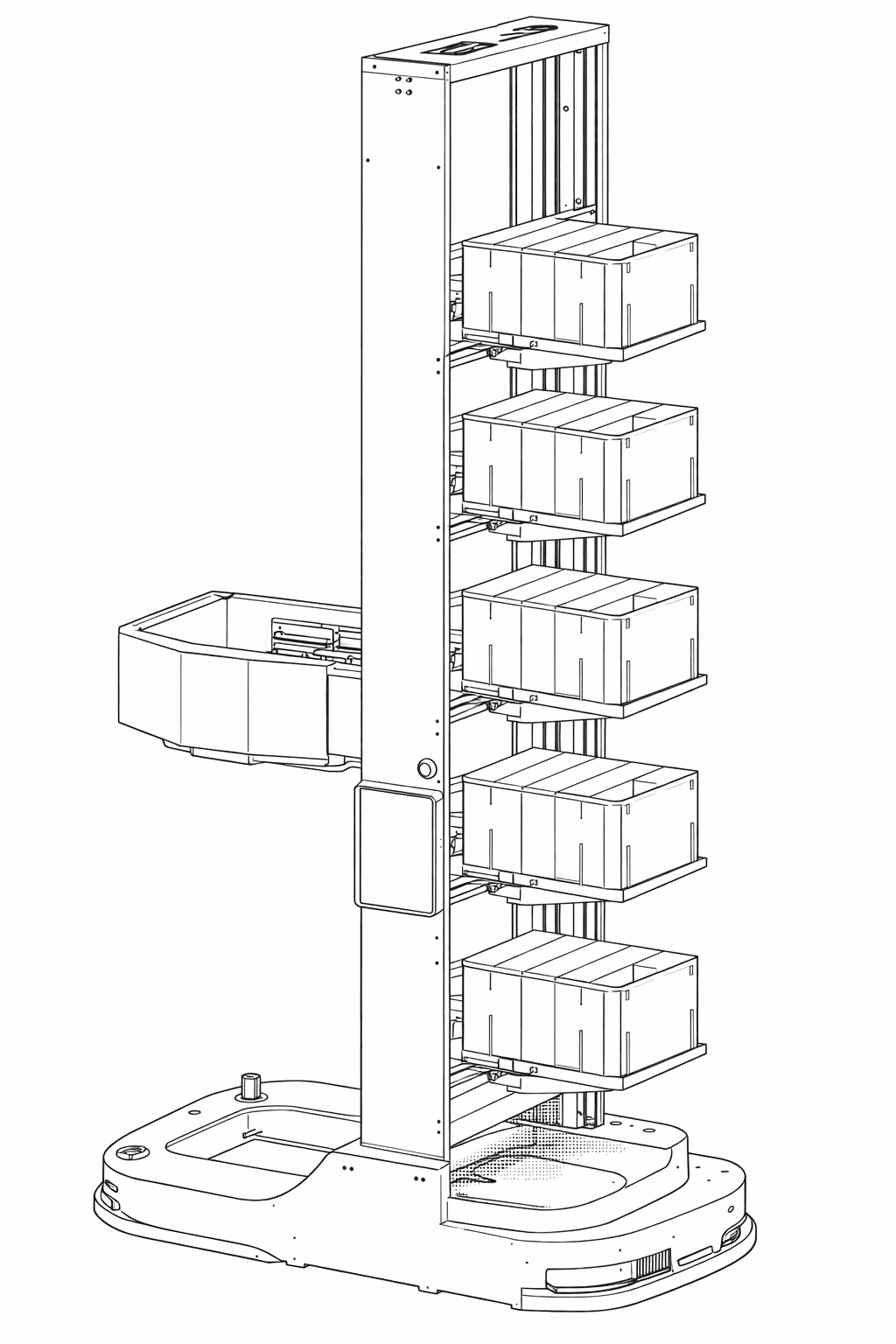

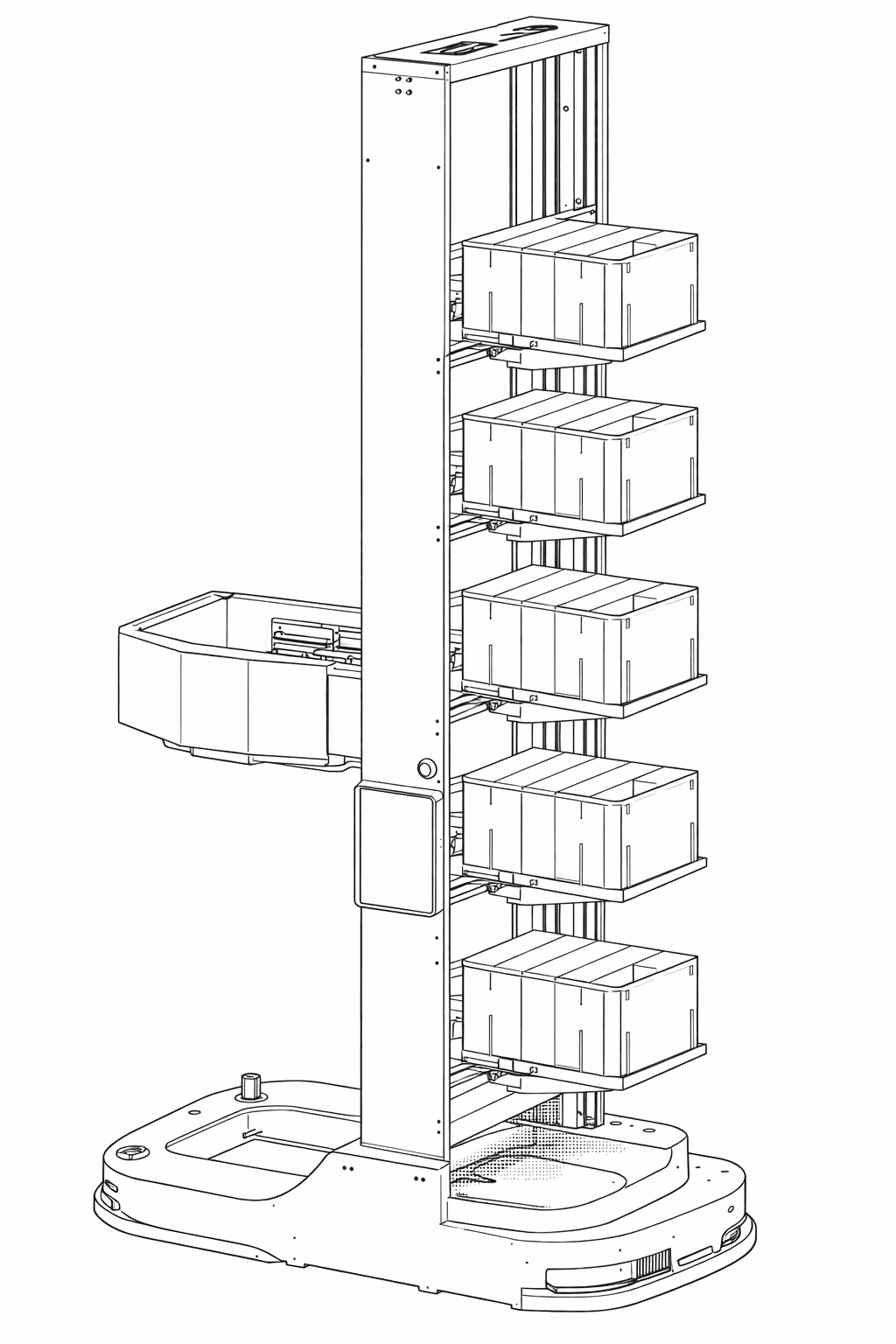

Z50-S

Z50-S

F0-50DC

F0-50DC

F0-50DCH

F0-50DCH

F-50A

F-50A

500 kg

Weight

220-5000 mm

Lifing height

300 kg

Rated load

1000 mm

Aisle width

880 mm

880 mm

1560 mm

Z50-S

6 pieces

Bin number

6 hrs

Run time

Rated speed

1.6 m/s

Position accuracy

± 10 mm

Charging time

1.2 hrs

Obstacle avoidance

LIDAR

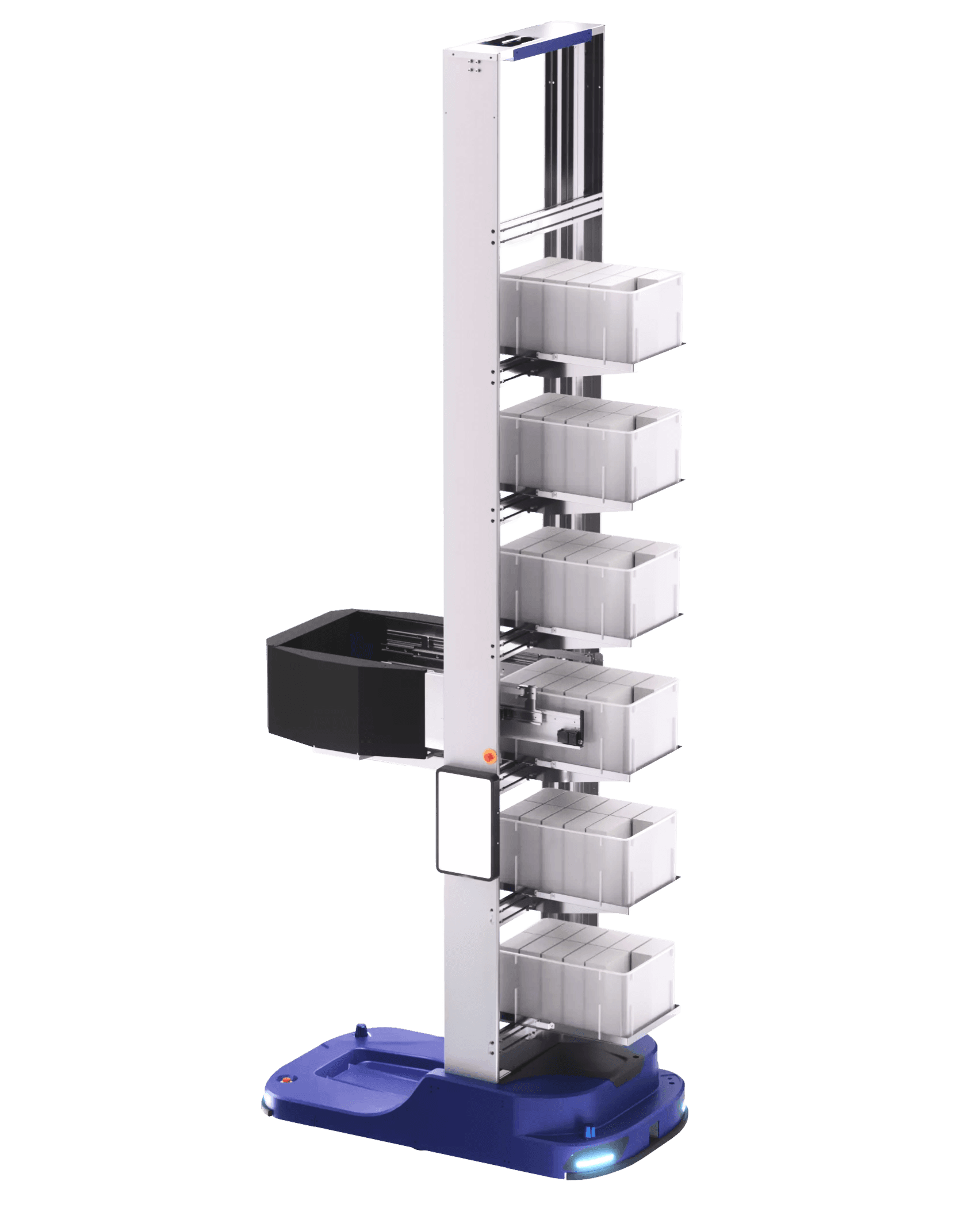

Robot portfolio

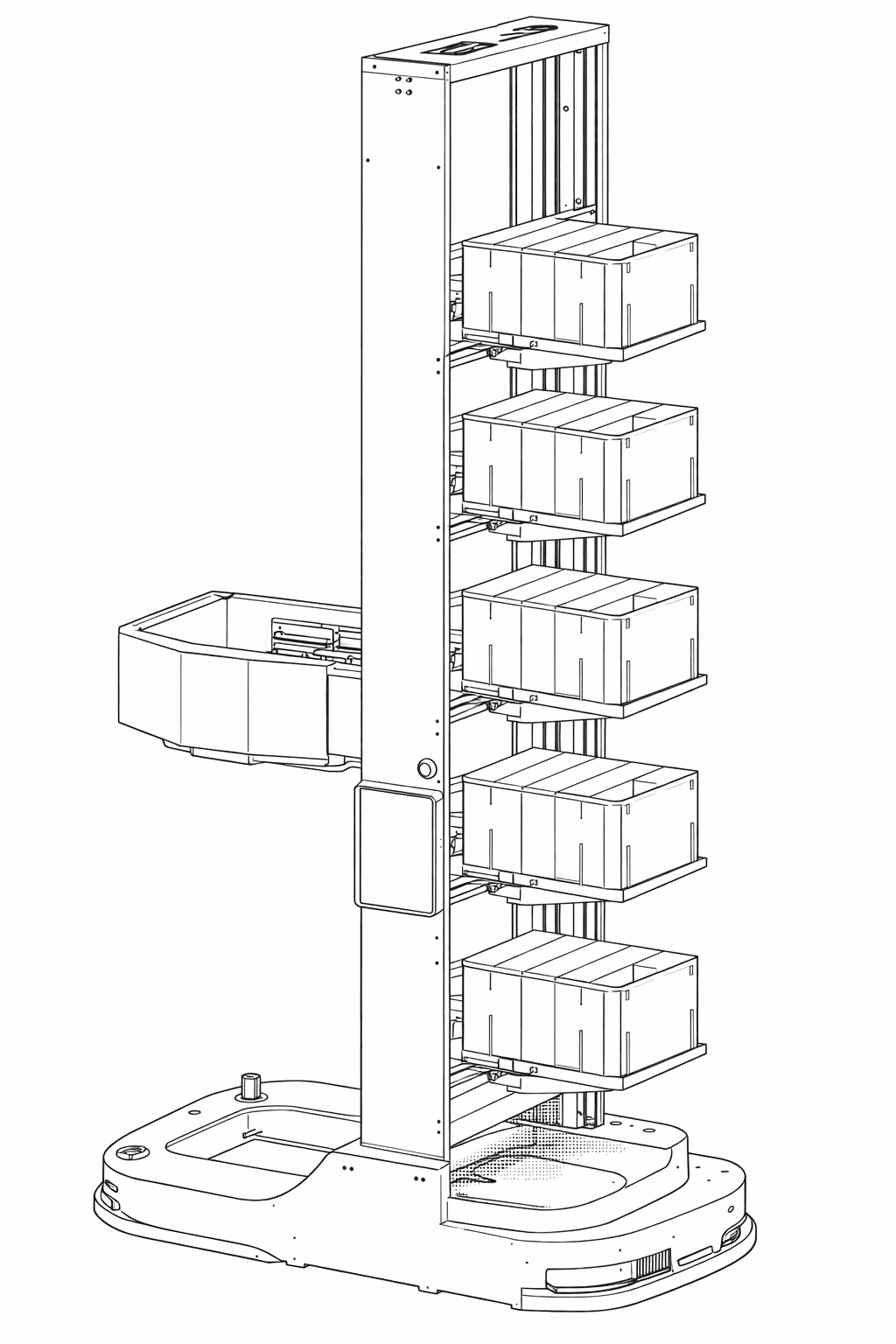

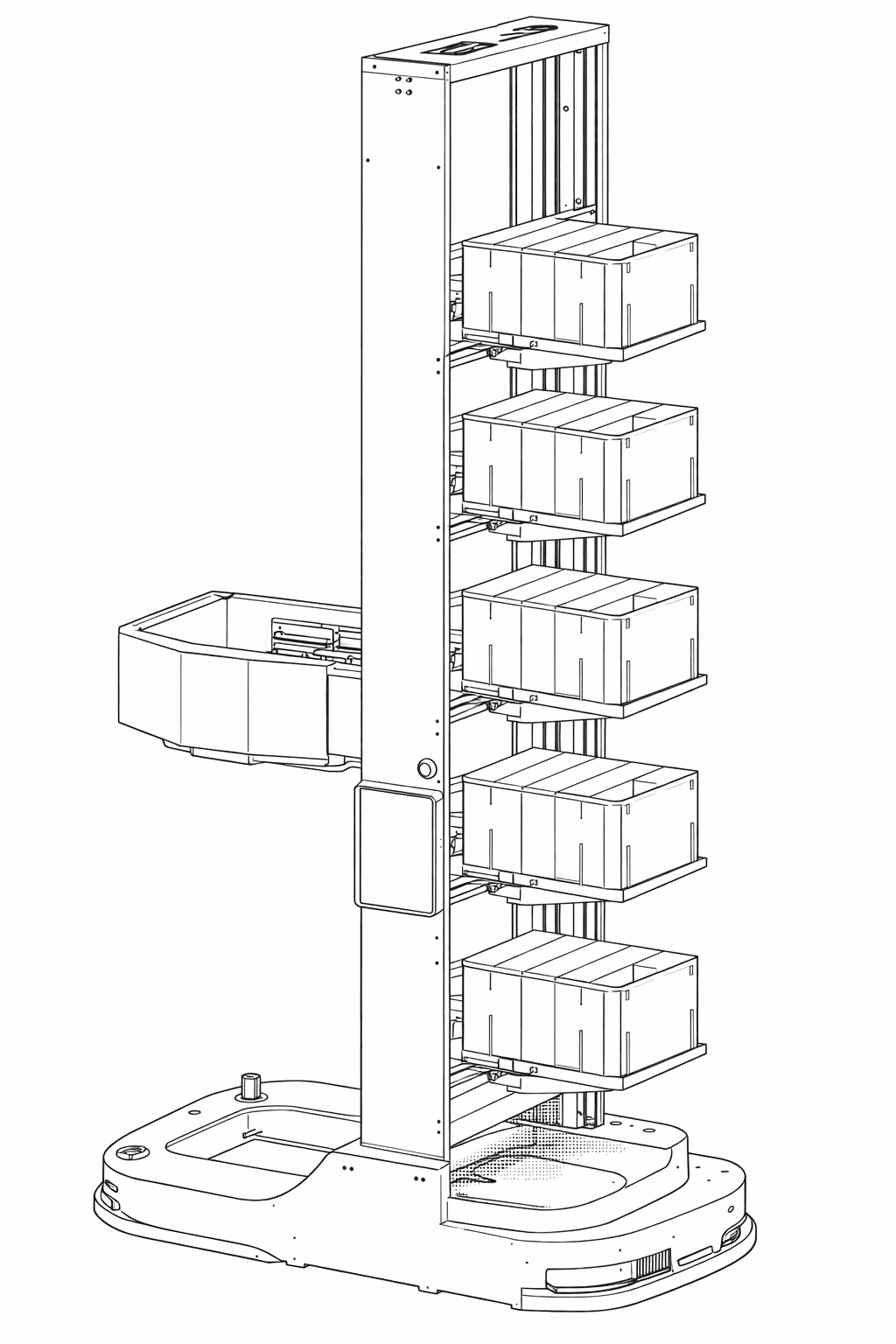

Z50-S

Z50-S

F0-50DC

F0-50DC

F0-50DCH

F0-50DCH

F-50A

F-50A

500 kg

Weight

220-5000 mm

Lifing height

300 kg

Rated load

1000 mm

Aisle width

880 mm

880 mm

1560 mm

Z50-S

6 pieces

Bin number

6 hrs

Run time

Rated speed

1.6 m/s

Position accuracy

± 10 mm

Charging time

1.2 hrs

Obstacle avoidance

LIDAR

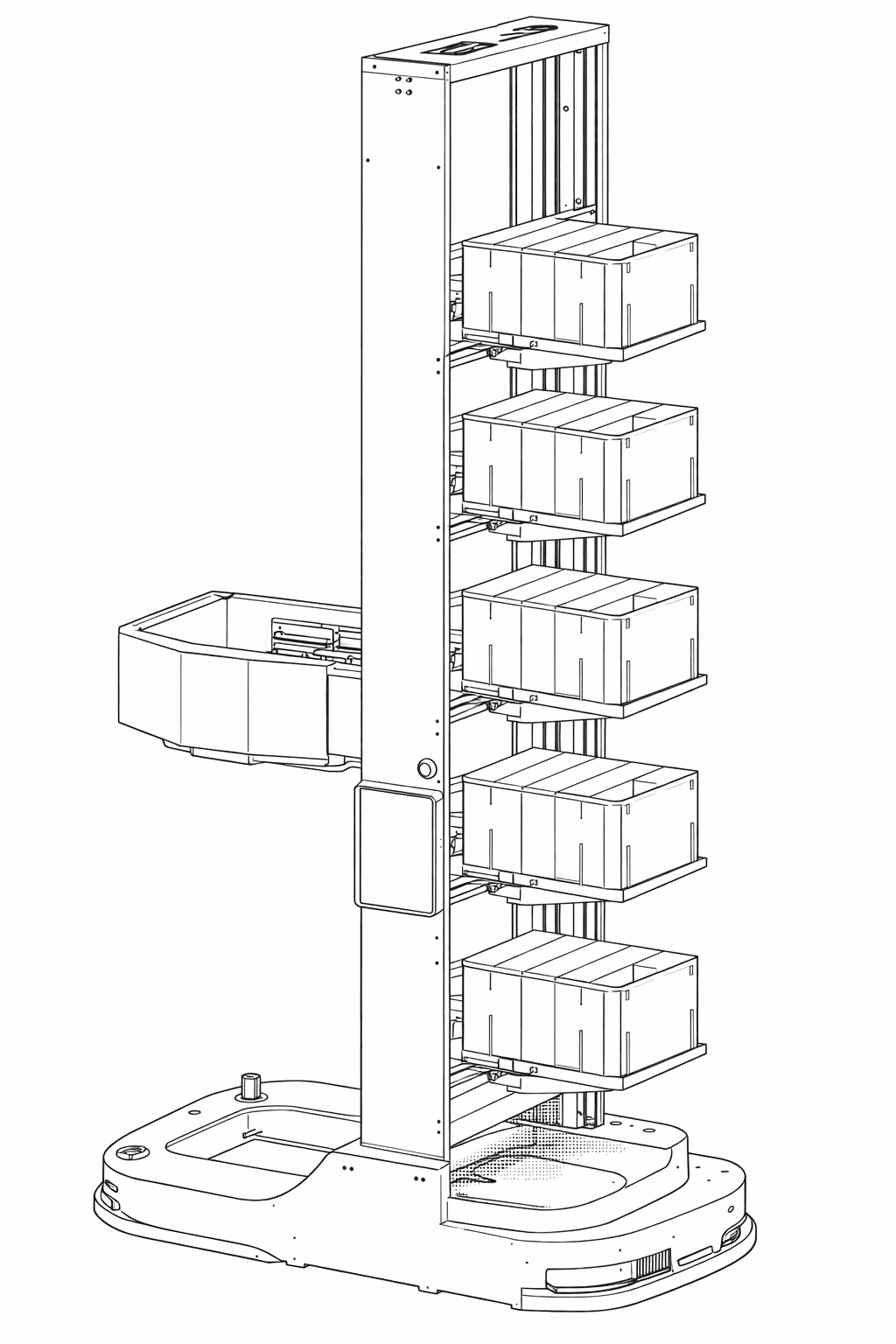

Robot portfolio

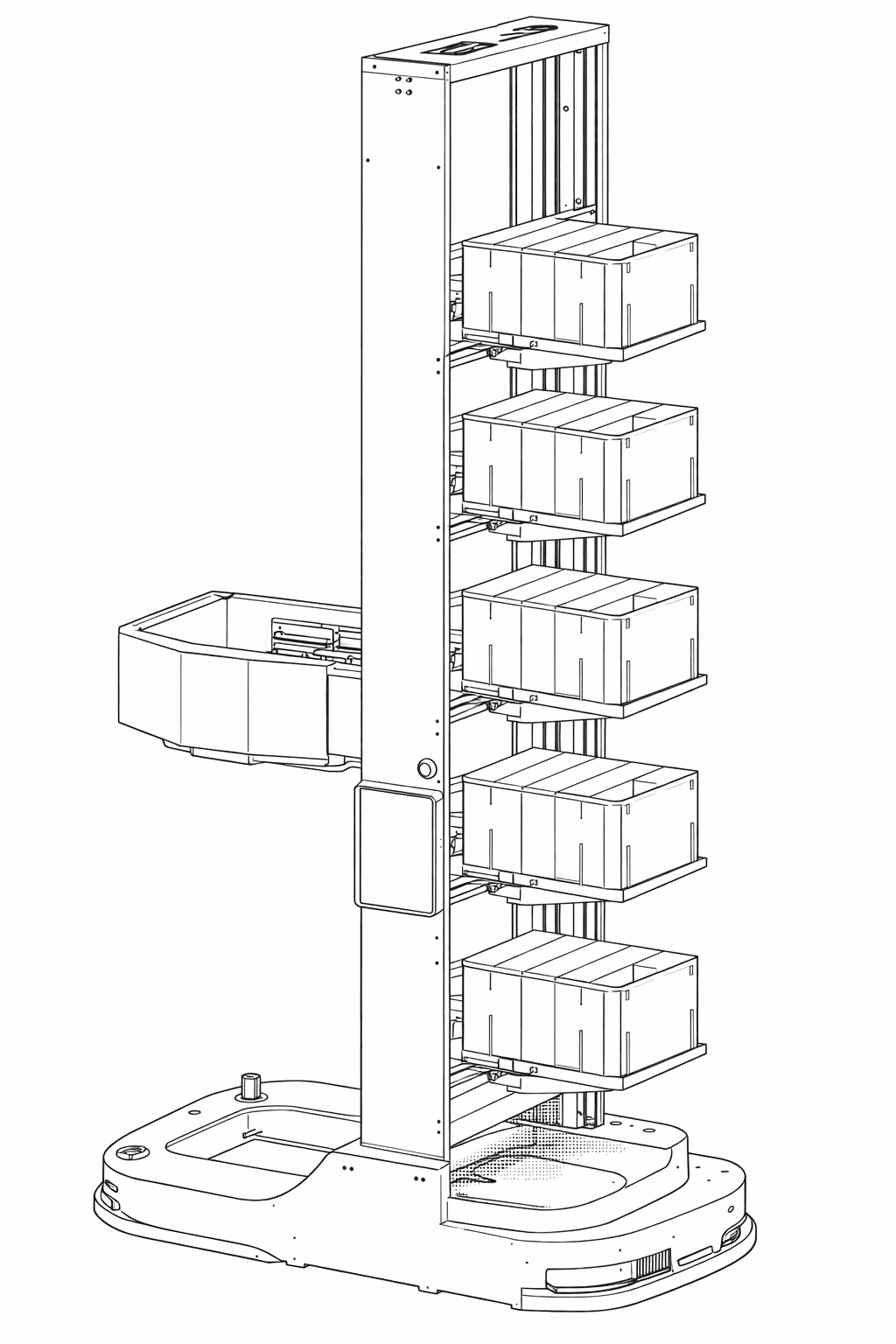

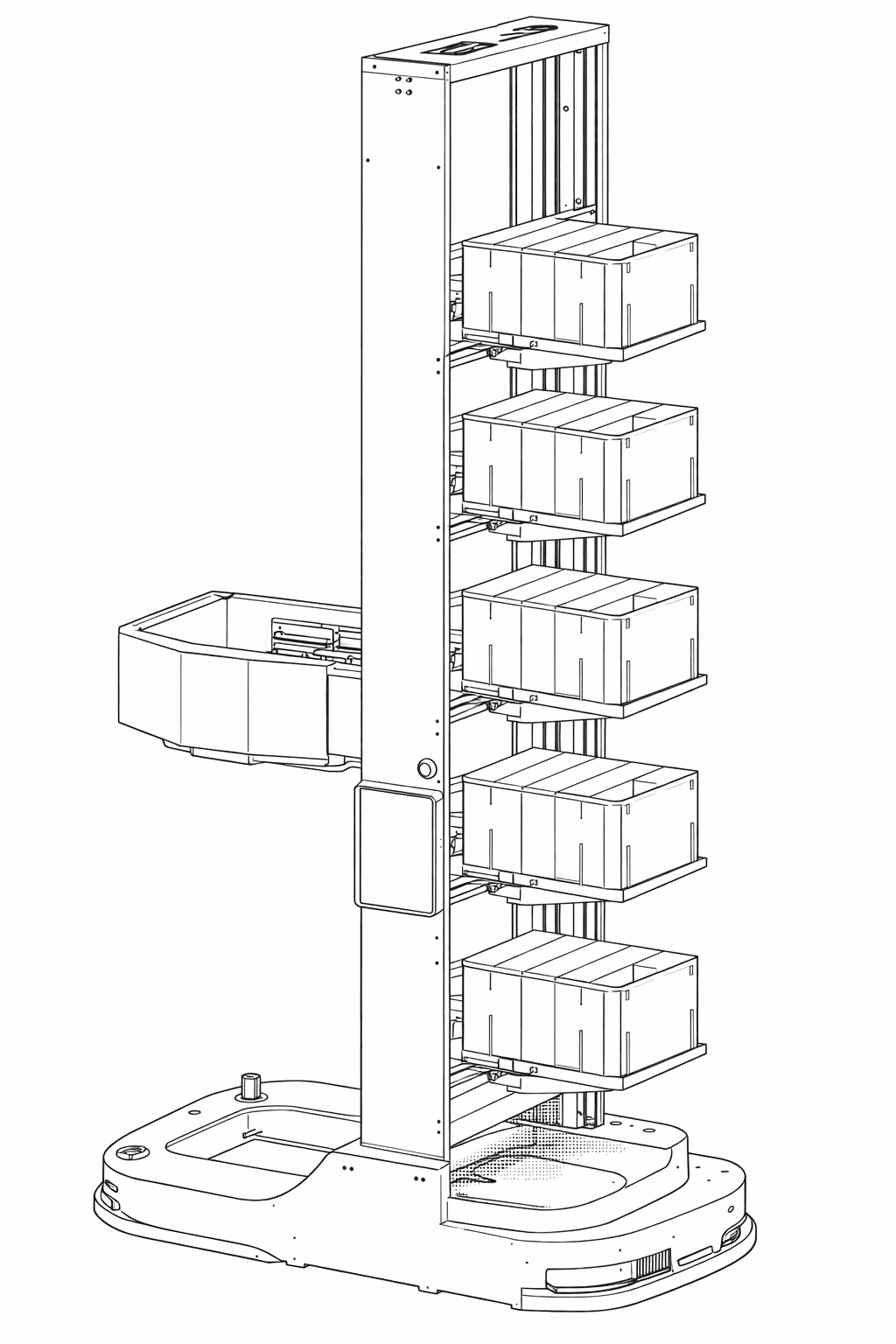

Z50-S

Z50-S

F0-50DC

F0-50DC

F0-50DCH

F0-50DCH

F-50A

F-50A

500 kg

Weight

300 kg

Rated load

220-5000 mm

Lifing height

1000 mm

Aisle width

880 mm

880 mm

1560 mm

Z50-S

6 pieces

Bin number

6 hrs

Run time

Rated speed

1.6 m/s

Position accuracy

± 10 mm

Charging time

1.2 hrs

Obstacle avoidance

LIDAR

Industries

Designed for diverse warehouse operations

Tote-to-Person approach, adapted to different industries, order profiles, and operational constraints.

SKU complexity: High

SKU complexity: High

SKU complexity: High

Results

Measurable business impact

Tote-to-Person systems create predictable, high-performance warehouse operations

by boosting picking efficiency and space utilisation.

Overcoming Labor Shortages

Even with a small workforce, robots boost warehouse productivity by automating repetitive tasks

Overcoming Labor Shortages

Even with a small workforce, robots boost warehouse productivity by automating repetitive tasks

Overcoming Labor Shortages

Even with a small workforce, robots boost warehouse productivity by automating repetitive tasks

50% Better Space Utilization

Automated systems enable up to 50% improvement in how warehouse space is used

50% Better Space Utilization

Automated systems enable up to 50% improvement in how warehouse space is used

50% Better Space Utilization

Automated systems enable up to 50% improvement in how warehouse space is used

Higher Accuracy and Efficiency

The system highlights the correct shelf, reducing errors and the costs associated with fixing them.

Higher Accuracy and Efficiency

The system highlights the correct shelf, reducing errors and the costs associated with fixing them.

Higher Accuracy and Efficiency

The system highlights the correct shelf, reducing errors and the costs associated with fixing them.

Increased Throughput

AI-driven routing optimizes robot movement, ensuring continuous material flow and enabling one worker to process more orders.

Increased Throughput

AI-driven routing optimizes robot movement, ensuring continuous material flow and enabling one worker to process more orders.

Increased Throughput

AI-driven routing optimizes robot movement, ensuring continuous material flow and enabling one worker to process more orders.

Accessible and Scalable

The best price-to-value ratio: fast integration, flexible deployment, and easy reconfiguration of warehouse layouts.

Accessible and Scalable

The best price-to-value ratio: fast integration, flexible deployment, and easy reconfiguration of warehouse layouts.

Accessible and Scalable

The best price-to-value ratio: fast integration, flexible deployment, and easy reconfiguration of warehouse layouts.