Shelf-to-Person

Autonomous robots bring shelves and pallets directly to pickers, reducing walk time and improving picking accuracy. Multi-vendor fleets are orchestrated through a single control layer for flexible, scalable warehouse operations.

Obstacles

Warehouse picking challenges

Labor dependency

Manual picking depends on labor availability, making operations vulnerable to turnover and seasonal fluctuations.

Labor dependency

Manual picking depends on labor availability, making operations vulnerable to turnover and seasonal fluctuations.

Labor dependency

Manual picking depends on labor availability, making operations vulnerable to turnover and seasonal fluctuations.

Peak throughput limits

Traditional picking models struggle to scale quickly, leading to missed SLAs and delayed shipments.

Peak throughput limits

Traditional picking models struggle to scale quickly, leading to missed SLAs and delayed shipments.

Peak throughput limits

Traditional picking models struggle to scale quickly, leading to missed SLAs and delayed shipments.

Inefficient space usage

Wide aisles and human-accessible layouts limit storage density, forcing warehouses to expand sooner or operate below capacity.

Inefficient space usage

Wide aisles and human-accessible layouts limit storage density, forcing warehouses to expand sooner or operate below capacity.

Inefficient space usage

Wide aisles and human-accessible layouts limit storage density, forcing warehouses to expand sooner or operate below capacity.

Long ROI cycles

Many automation projects require heavy infrastructure changes and long ROI timelines.

Long ROI cycles

Many automation projects require heavy infrastructure changes and long ROI timelines.

Long ROI cycles

Many automation projects require heavy infrastructure changes and long ROI timelines.

Solution

How Shelf-to-Person solution improves picking

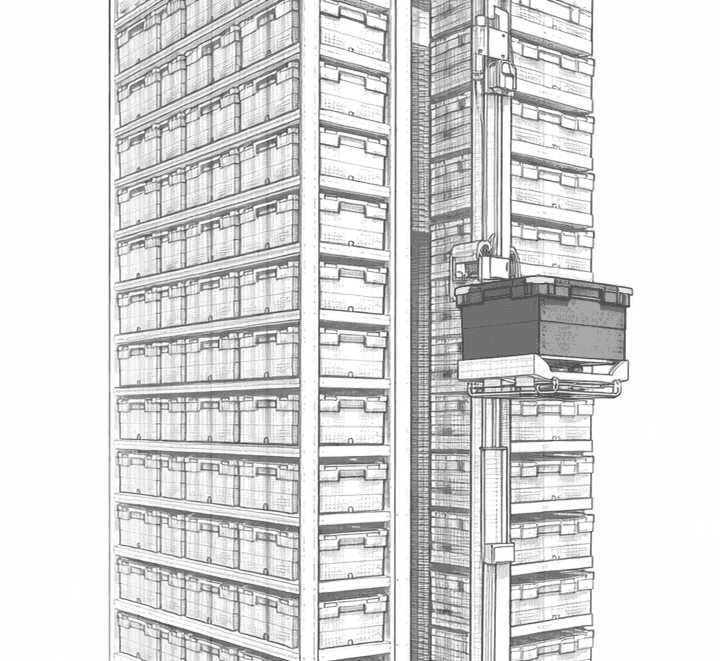

Higher density through robotic layouts

Shelf-to-person layouts eliminate the need for wide aisles and manual access, enabling higher-density storage.

Higher density through robotic layouts

Shelf-to-person layouts eliminate the need for wide aisles and manual access, enabling higher-density storage.

Higher density through robotic layouts

Shelf-to-person layouts eliminate the need for wide aisles and manual access, enabling higher-density storage.

How it works

Shelf-to-Person picking workflow

Deus Robotics offers a wide range of shelf-to-person robots designed for different warehouse layouts and operational needs. While the models may vary, they all follow the same simple workflow to bring inventory directly to your operators

Receive tasks

WMS sends pick instructions to the robot, including items and storage locations.

01

Receive tasks

WMS sends pick instructions to the robot, including items and storage locations.

01

Navigate safely

Robots move through the warehouse using advanced sensors and intelligent navigation, avoiding obstacles.

02

Navigate safely

Robots move through the warehouse using advanced sensors and intelligent navigation, avoiding obstacles.

02

Pick shelves

Required shelves are retrieved, and items are securely positioned for transport.

03

Pick shelves

Required shelves are retrieved, and items are securely positioned for transport.

03

Deliver to picker

Shelves arrive at the picking station, allowing operators to pick items quickly and accurately.

04

Deliver to picker

Shelves arrive at the picking station, allowing operators to pick items quickly and accurately.

04

Update inventory

The WMS is updated in real time, reflecting completed picks and current stock levels.

05

Update inventory

The WMS is updated in real time, reflecting completed picks and current stock levels.

05

Management with

Deus RMS

Our Robot Management System unifies all robots and seamlessly integrates with your warehouse systems.

06

Management with

Deus RMS

Our Robot Management System unifies all robots and seamlessly integrates with your warehouse systems.

06

Robot portfolio

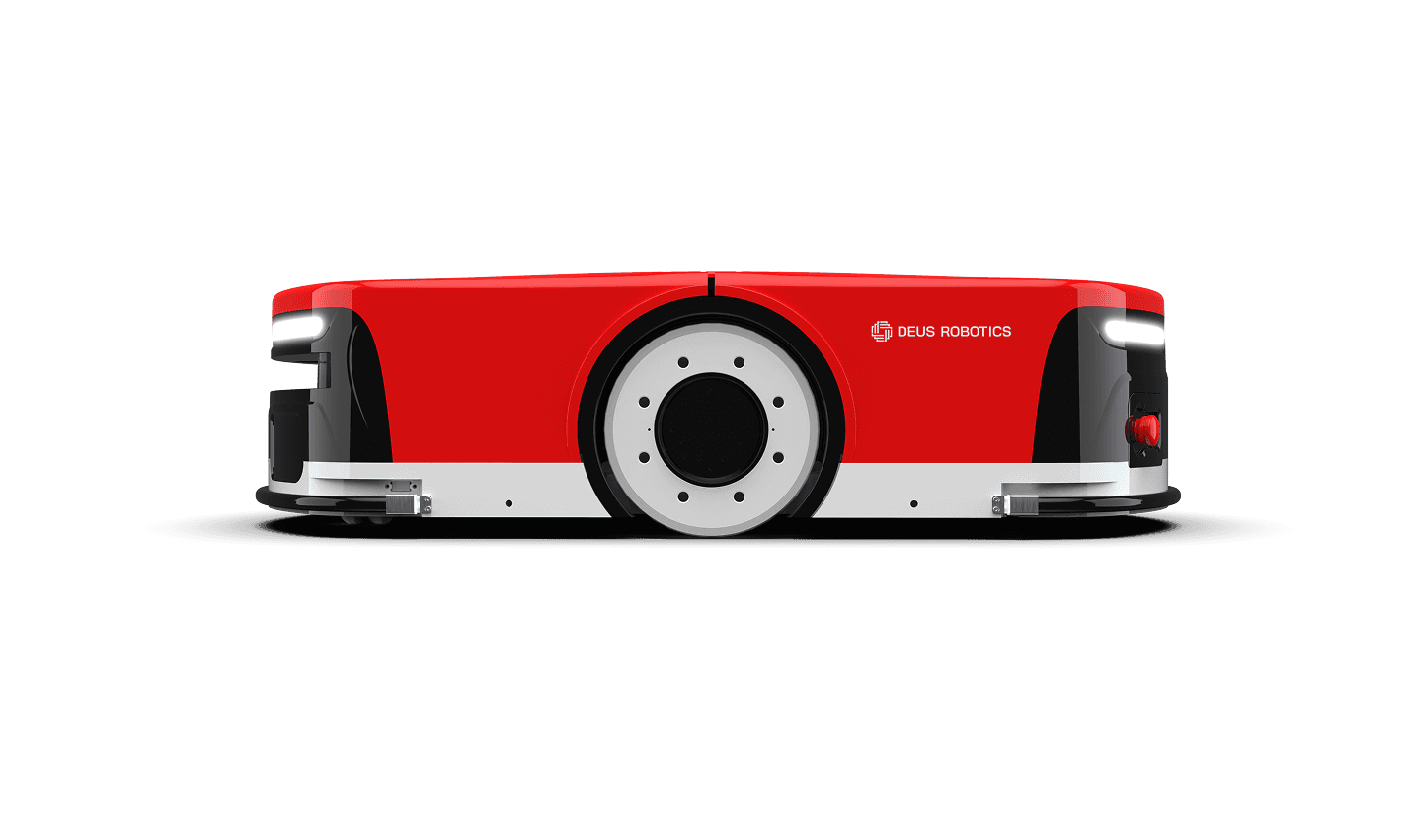

T6-800

T6-800

T6-1200/1500

T6-1200/1500

M6-300

M6-300

M6-600

M6-600

Q2-400D

Q2-400D

Q3-600D

Q3-600D

Q7-1000E

Q7-1000E

160 kg

Weight

60 mm

Lifing height

800 kg

Rated load

980 mm

Rotation diameter

680 mm

245 mm

980 mm

T6-800

SLAM

Navigation

8 hrs

Run time

Rated speed

2.2 m/s

Position accuracy

± 10 mm

Charging time

1.5 hrs

Robot portfolio

T6-800

T6-800

T6-1200/1500

T6-1200/1500

M6-300

M6-300

M6-600

M6-600

Q2-400D

Q2-400D

Q3-600D

Q3-600D

Q7-1000E

Q7-1000E

160 kg

Weight

800 kg

Rated load

60 mm

Lifing height

980 mm

Rotation diameter

680 mm

245 mm

980 mm

T6-800

SLAM

Navigation

8 hrs

Run time

Rated speed

2.2 m/s

Position accuracy

± 10 mm

Charging time

1.5 hrs

Robot portfolio

T6-800

T6-800

T6-1200/1500

T6-1200/1500

M6-300

M6-300

M6-600

M6-600

Q2-400D

Q2-400D

Q3-600D

Q3-600D

Q7-1000E

Q7-1000E

160 kg

Weight

60 mm

Lifing height

800 kg

Rated load

980 mm

Rotation diameter

680 mm

245 mm

980 mm

T6-800

SLAM

Navigation

8 hrs

Run time

Rated speed

2.2 m/s

Position accuracy

± 10 mm

Charging time

1.5 hrs

Contact us

No two warehouses are the same – high customization is the key

This portfolio shows only a fraction of what’s available; we source, combine, and orchestrate any robot models through Deus RMS to fit your workflows and performance targets

Industries

Designed for diverse warehouse operations

Shelf-to-Person approach, adapted to different industries, order profiles, and operational constraints.

SKU complexity: High

SKU complexity: High

SKU complexity: High

Results

Measurable business impact

Our shelf-to-person robots transform warehouse workflows by delivering inventory directly to operators, improving performance, and optimising operations.

Performance impact

Up to 400%

Higher storage density

Up to 400%

Higher storage density

Up to 400%

Higher storage density

4-5 times

Higher picking efficiency compared to manual operations

4-5 times

Higher picking efficiency compared to manual operations

4-5 times

Higher picking efficiency compared to manual operations

Up to 300

Tote presentations per hour at a single MIX workstation

Up to 300

Tote presentations per hour at a single MIX workstation

Up to 300

Tote presentations per hour at a single MIX workstation

200-300%

Overall picking efficiency increase versus traditional picking methods

200-300%

Overall picking efficiency increase versus traditional picking methods

200-300%

Overall picking efficiency increase versus traditional picking methods

Operational impact

Increased picks

Significant increase in picks per hour per operator, allowing your team to focus on higher-value tasks

Increased picks

Significant increase in picks per hour per operator, allowing your team to focus on higher-value tasks

Increased picks

Significant increase in picks per hour per operator, allowing your team to focus on higher-value tasks

Higher space utilization

Higher space utilization without facility expansion, enabling greater throughput within the existing footprint

Higher space utilization

Higher space utilization without facility expansion, enabling greater throughput within the existing footprint

Higher space utilization

Higher space utilization without facility expansion, enabling greater throughput within the existing footprint

Peak periods perfomance

Predictable performance during peak periods, ensuring smooth operations and on-time order fulfillment

Peak periods perfomance

Predictable performance during peak periods, ensuring smooth operations and on-time order fulfillment

Peak periods perfomance

Predictable performance during peak periods, ensuring smooth operations and on-time order fulfillment

Low operational risk

Lower operational risk and faster scaling as volumes grow

Low operational risk

Lower operational risk and faster scaling as volumes grow

Low operational risk

Lower operational risk and faster scaling as volumes grow