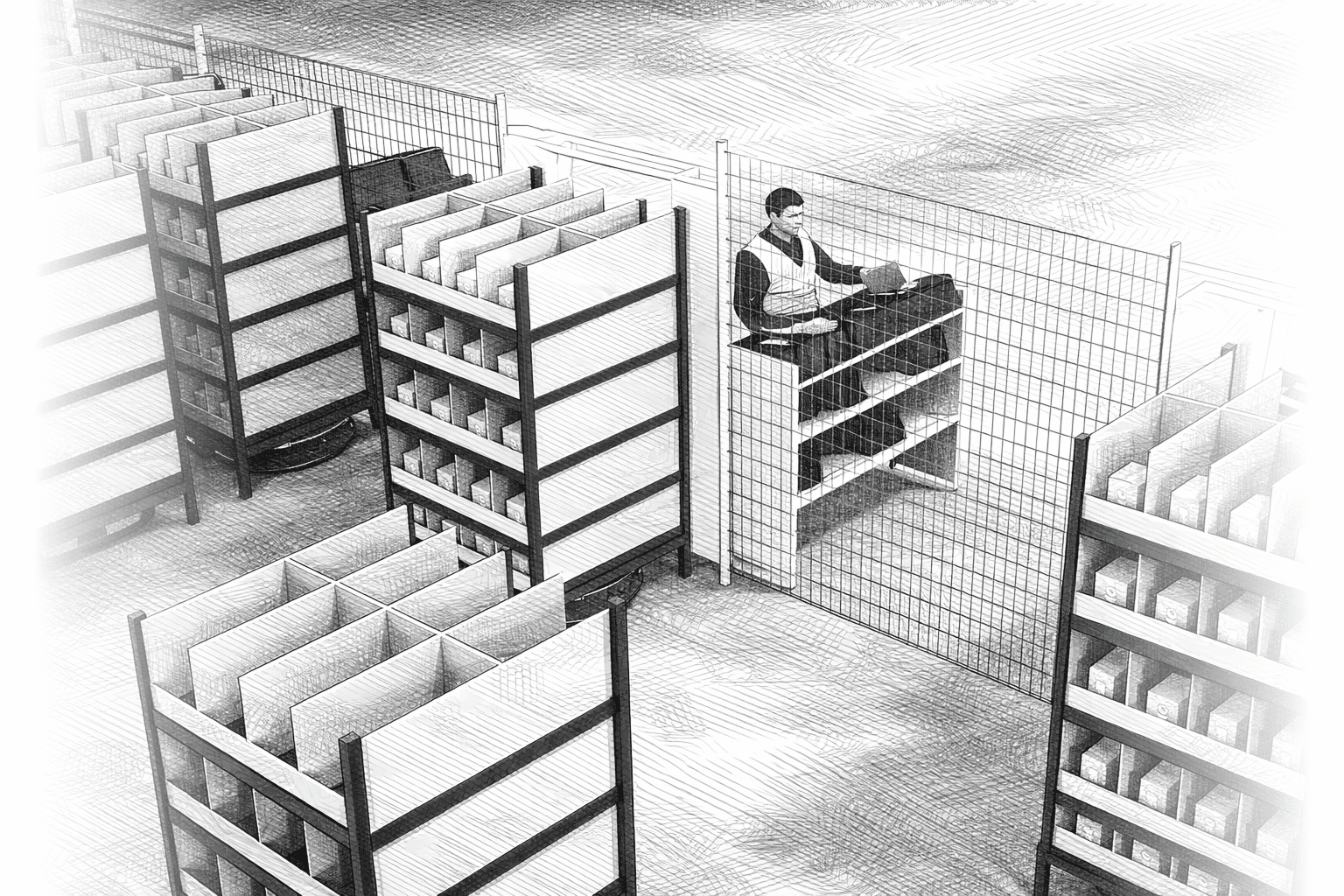

Pallet-to-Person Picking

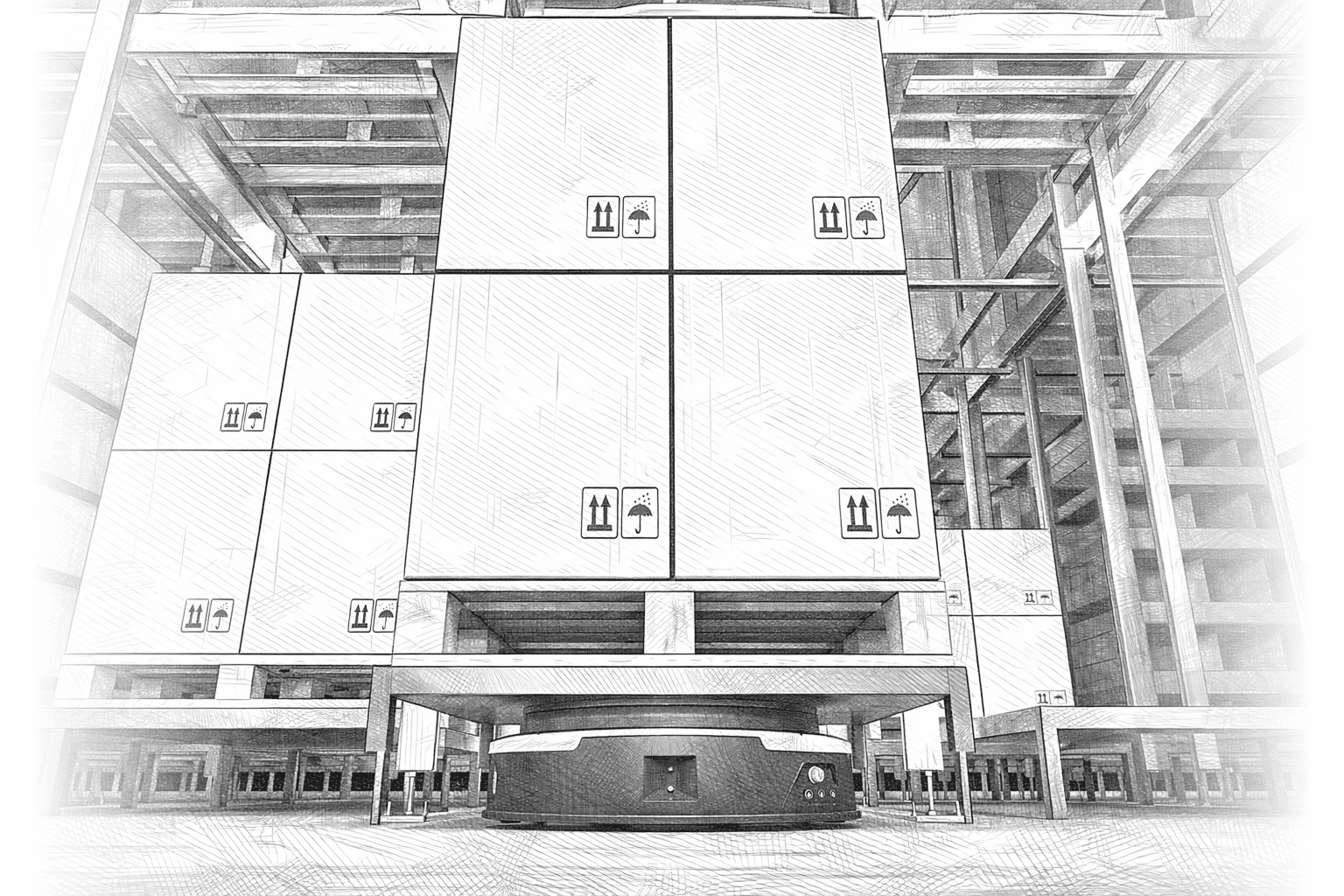

Autonomous pallet-to-person robots deliver pallets directly to pickers, reducing travel time and errors. A single control layer orchestrates multi-vendor pallet picking systems for scalable, high-throughput warehouse operations.

Obstacles

Challenges in pallet-based warehouse picking

Mixed pallet complexity

Handling full pallets, mixed pallets, and case picks slows pallet picking and increases errors as assortment and load complexity grow.

Mixed pallet complexity

Handling full pallets, mixed pallets, and case picks slows pallet picking and increases errors as assortment and load complexity grow.

Mixed pallet complexity

Handling full pallets, mixed pallets, and case picks slows pallet picking and increases errors as assortment and load complexity grow.

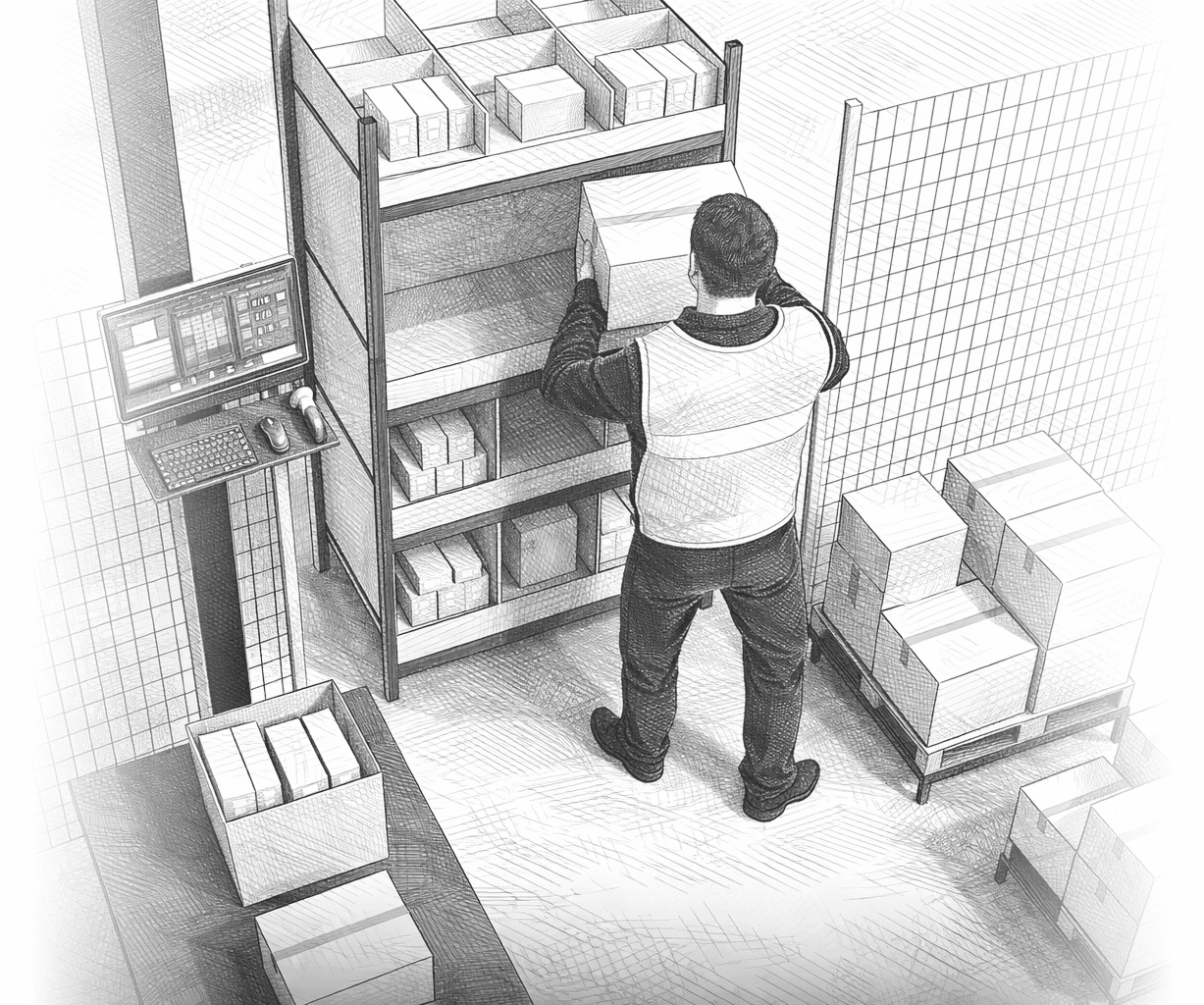

Manual pallet positioning delays

Manual scanning and pallet alignment delay workstation presentation, increasing cycle times and limiting continuous pallet picking throughput.

Manual pallet positioning delays

Manual scanning and pallet alignment delay workstation presentation, increasing cycle times and limiting continuous pallet picking throughput.

Manual pallet positioning delays

Manual scanning and pallet alignment delay workstation presentation, increasing cycle times and limiting continuous pallet picking throughput.

Outbound peak congestion

During peak volumes, manual pallet movement creates forklift congestion, queues, and staging bottlenecks, leading to SLA risks.

Outbound peak congestion

During peak volumes, manual pallet movement creates forklift congestion, queues, and staging bottlenecks, leading to SLA risks.

Outbound peak congestion

During peak volumes, manual pallet movement creates forklift congestion, queues, and staging bottlenecks, leading to SLA risks.

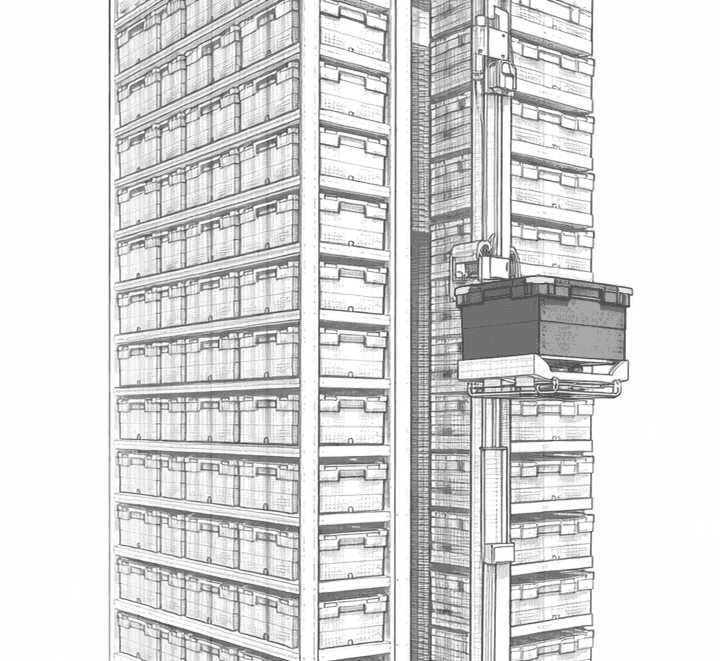

Inefficient use of vertical pallet storage

High-bay racking is designed for storage, not fast picking. Manual retrieval from upper levels increases travel time, reduces pick frequency, and adds safety constraints.

Inefficient use of vertical pallet storage

High-bay racking is designed for storage, not fast picking. Manual retrieval from upper levels increases travel time, reduces pick frequency, and adds safety constraints.

Inefficient use of vertical pallet storage

High-bay racking is designed for storage, not fast picking. Manual retrieval from upper levels increases travel time, reduces pick frequency, and adds safety constraints.

Limited flexibility in pallet operations

Traditional pallet workflows rely on fixed processes. Changing routes, priorities, or capacity often requires manual coordination, slowing response to demand.

Limited flexibility in pallet operations

Traditional pallet workflows rely on fixed processes. Changing routes, priorities, or capacity often requires manual coordination, slowing response to demand.

Limited flexibility in pallet operations

Traditional pallet workflows rely on fixed processes. Changing routes, priorities, or capacity often requires manual coordination, slowing response to demand.

Throughput capped by safety constraints

Safety-driven limits on pallet flow and buffering reduce effective throughput at picking stations, creating idle time even during high-demand periods.

Throughput capped by safety constraints

Safety-driven limits on pallet flow and buffering reduce effective throughput at picking stations, creating idle time even during high-demand periods.

Throughput capped by safety constraints

Safety-driven limits on pallet flow and buffering reduce effective throughput at picking stations, creating idle time even during high-demand periods.

Solution

How Pallet-to-Person solves warehouse challenges

Scalable pallet flow during peak volumes

Orchestrated robot fleets increase pallet throughput during outbound peaks without adding forklifts, congestion, or costly workflow changes.

Scalable pallet flow during peak volumes

Orchestrated robot fleets increase pallet throughput during outbound peaks without adding forklifts, congestion, or costly workflow changes.

Scalable pallet flow during peak volumes

Orchestrated robot fleets increase pallet throughput during outbound peaks without adding forklifts, congestion, or costly workflow changes.

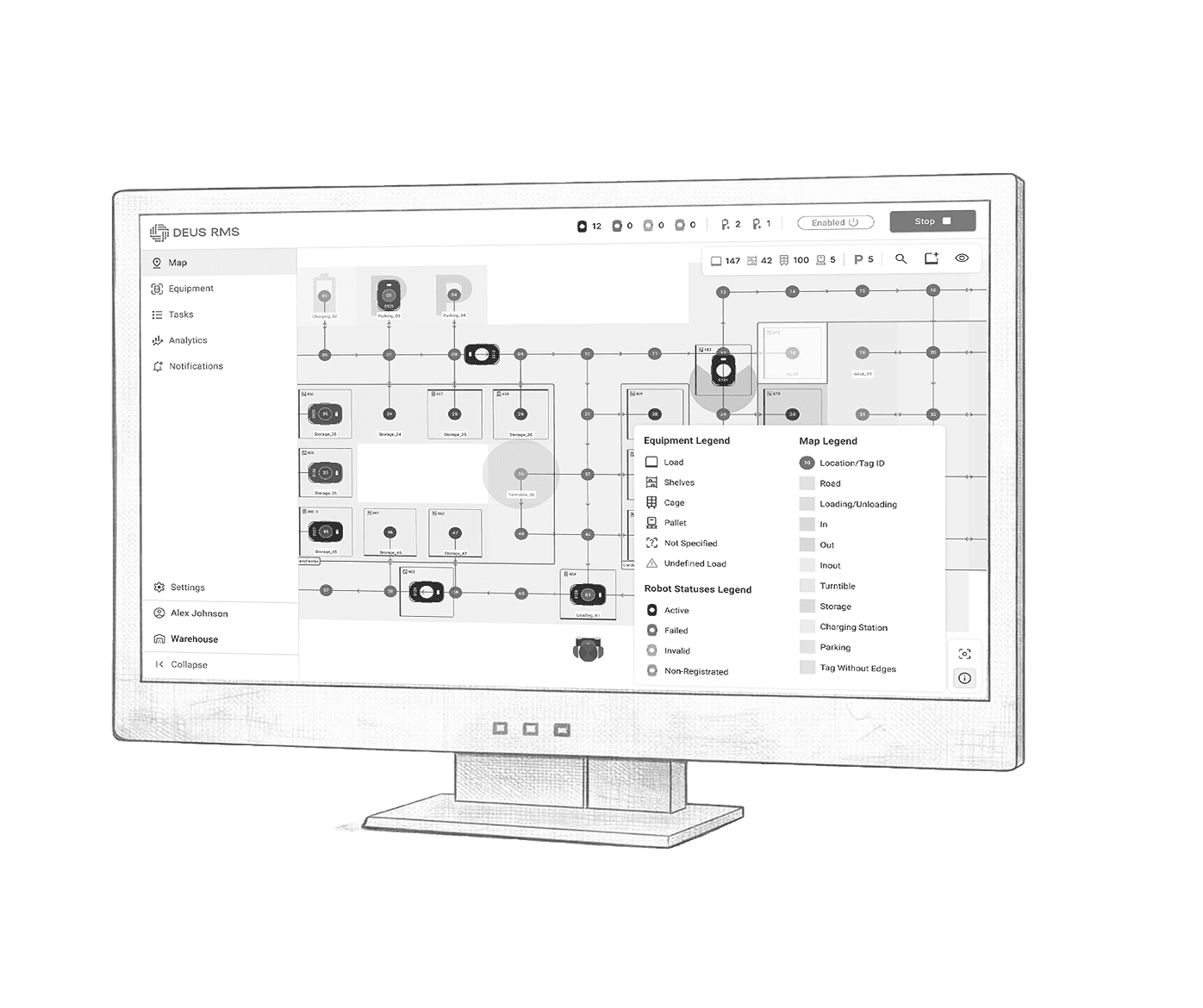

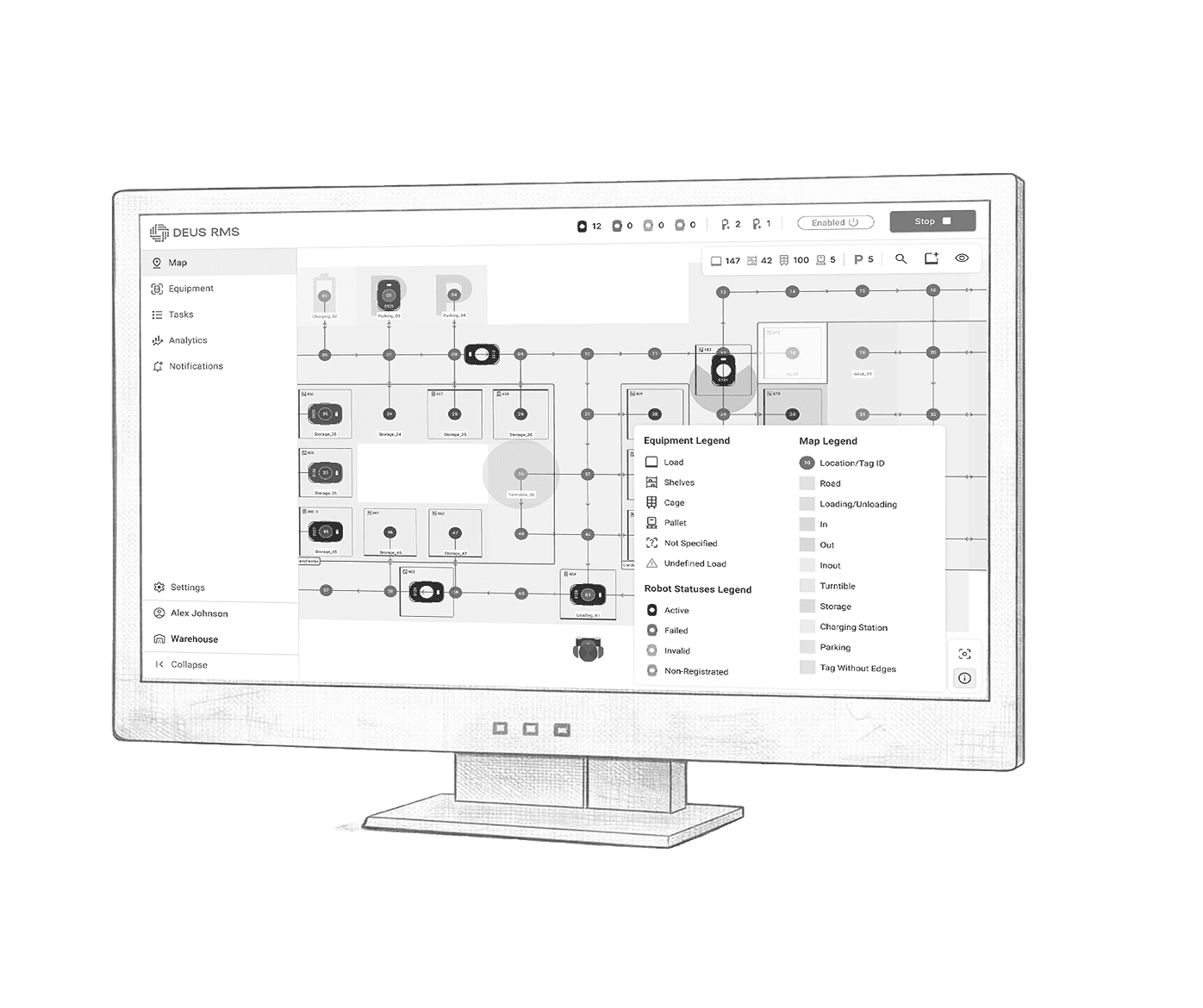

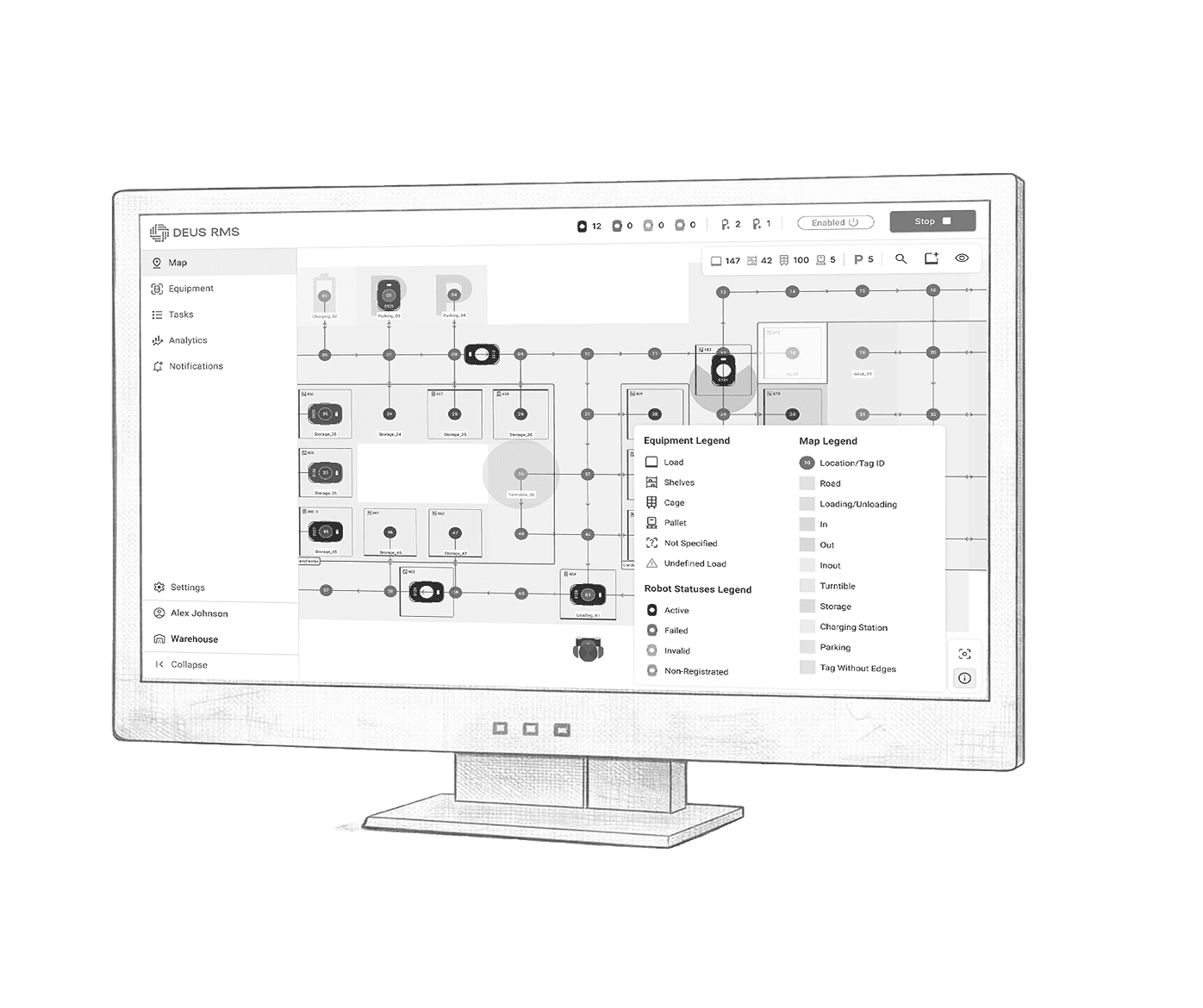

Predictable pallet operations under full control

A centralized execution layer allows pallet operations to adapt to change while maintaining visibility, stability, and control as volumes and complexity grow.

Predictable pallet operations under full control

A centralized execution layer allows pallet operations to adapt to change while maintaining visibility, stability, and control as volumes and complexity grow.

Predictable pallet operations under full control

A centralized execution layer allows pallet operations to adapt to change while maintaining visibility, stability, and control as volumes and complexity grow.

Robot portfolio

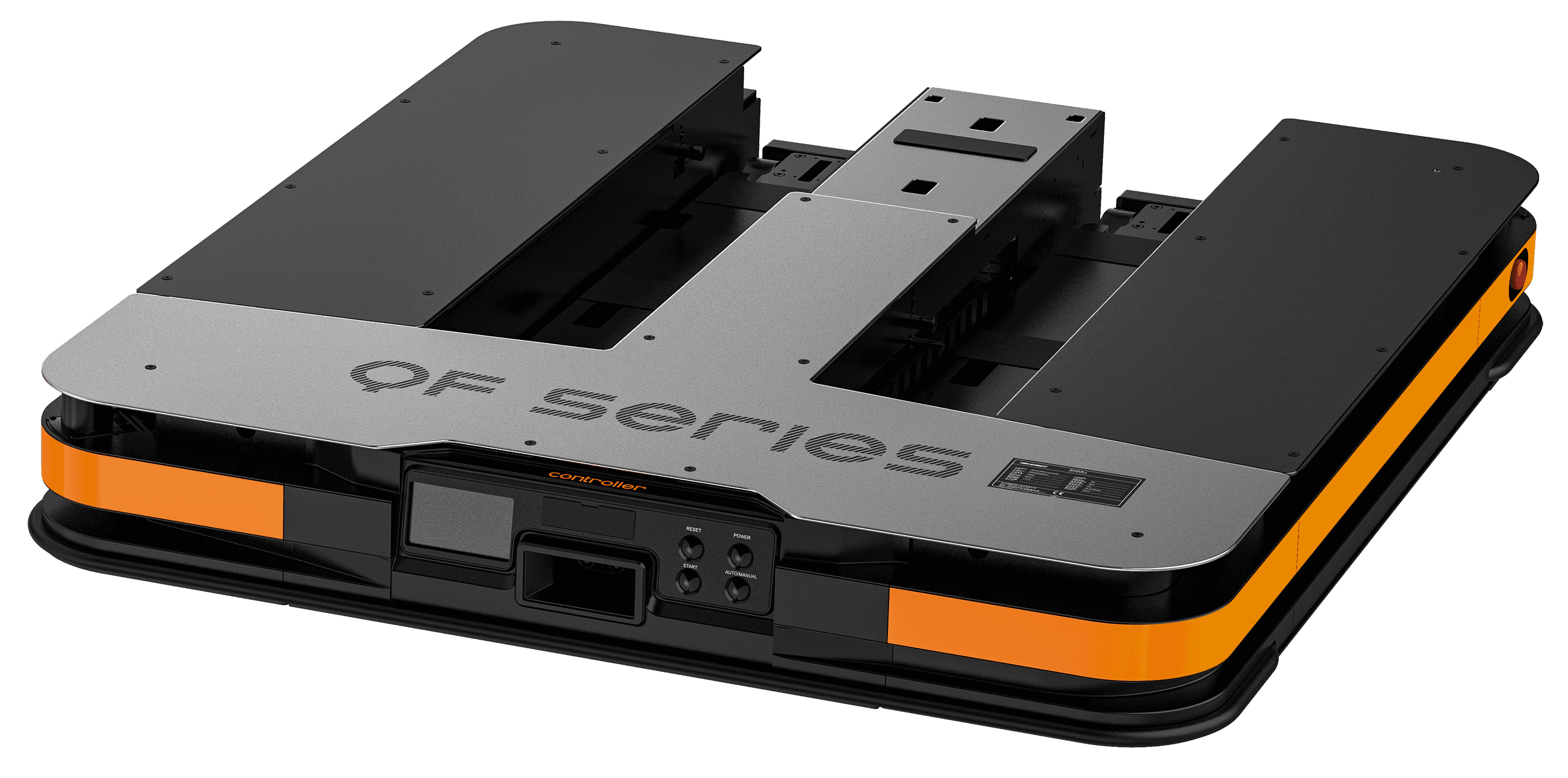

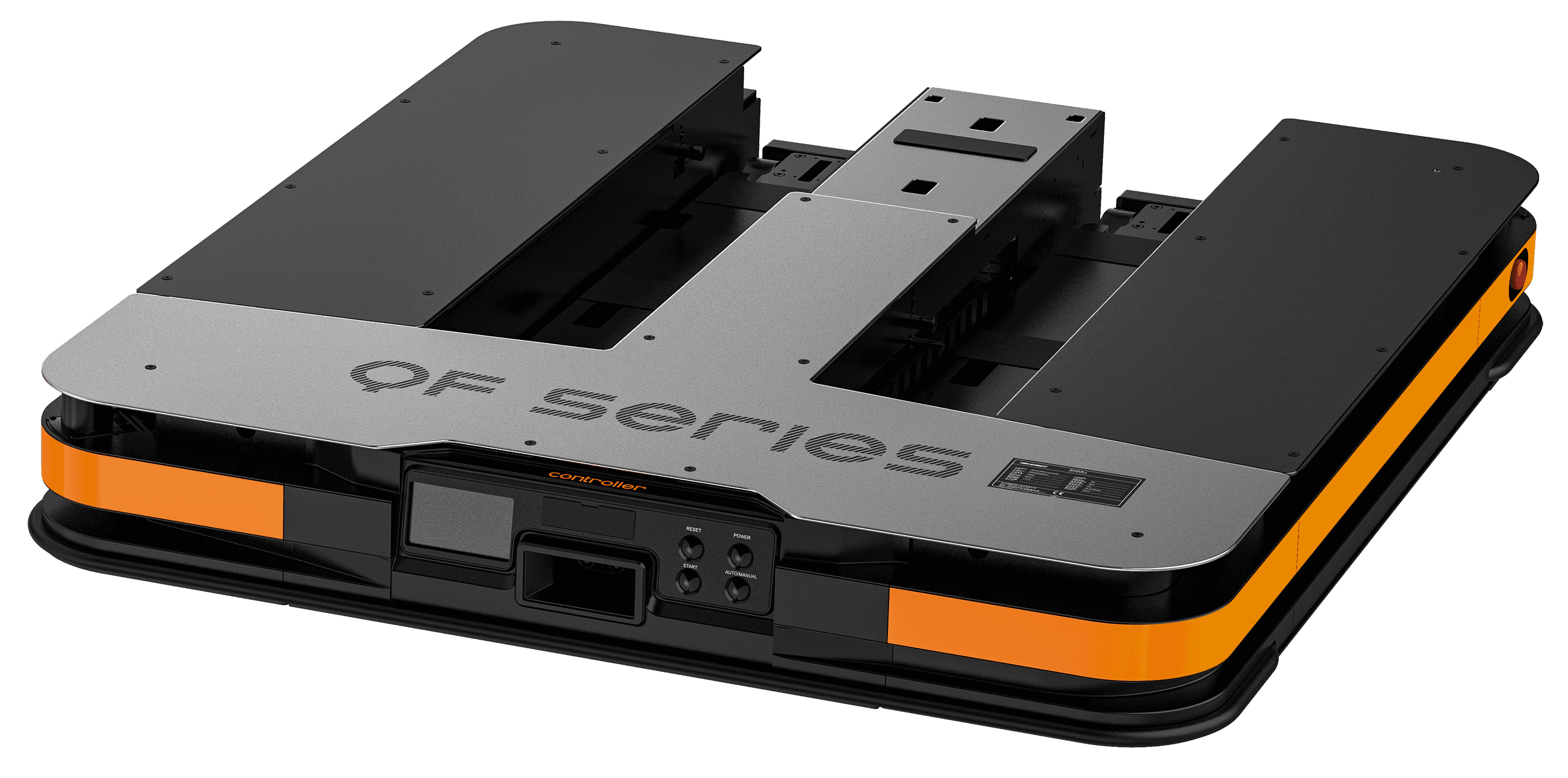

QF-1000D

QF-1000D

F4-2000

F4-2000

Q3-600

Q3-600

334 kg

Weight

1640 mm

Rotation diameter

1000 kg

Rated load

1200 mm

190 mm

1250 mm

QF-1000D

SLAM

Navigation

6-8 hrs

Run time

Rated speed

1.8-2 m/s

Position accuracy

± 10 mm

Charging time

≤1.5 hrs

Robot portfolio

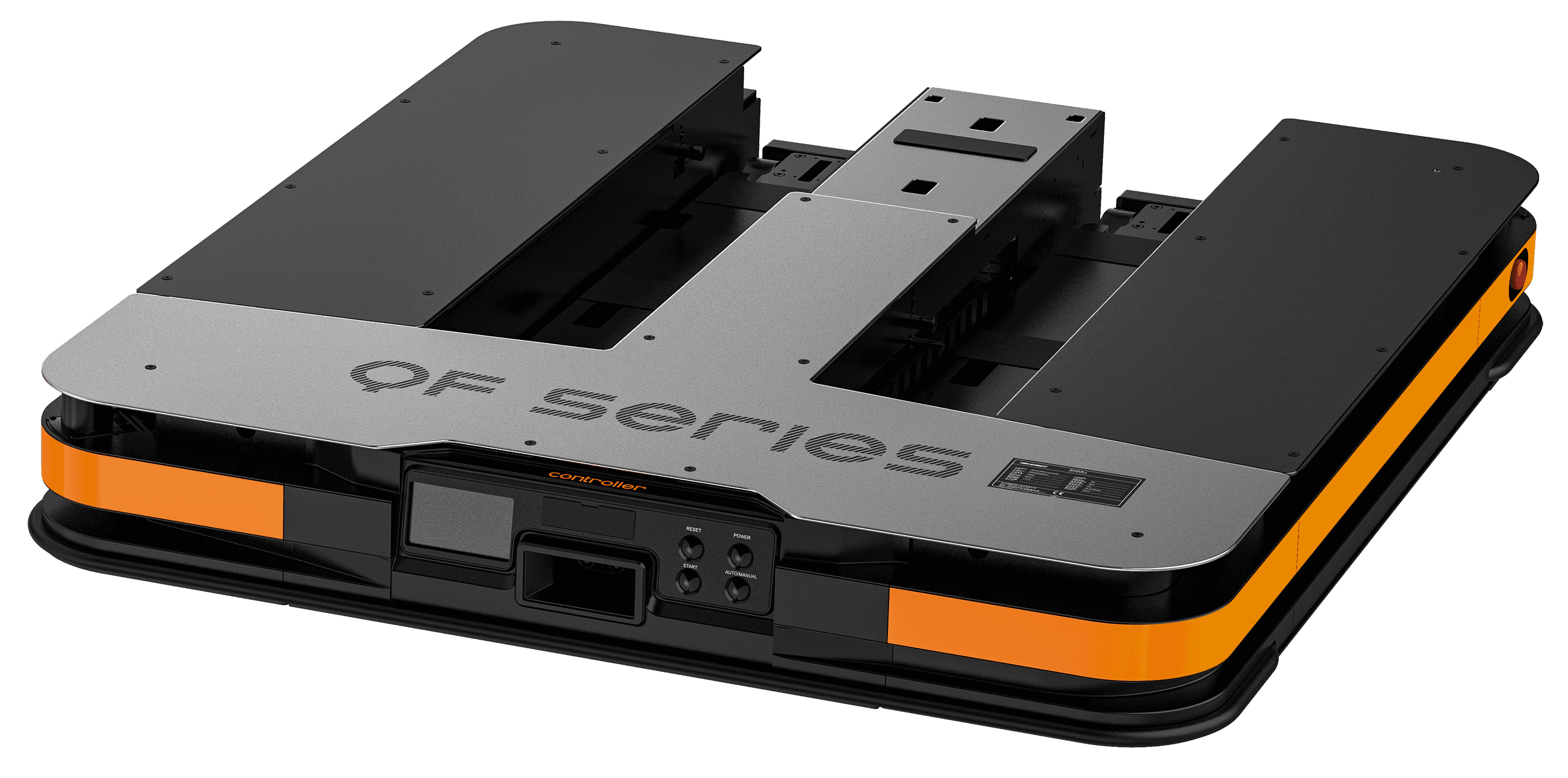

QF-1000D

QF-1000D

F4-2000

F4-2000

Q3-600

Q3-600

334 kg

Weight

1000 kg

Rated load

1640 mm

Rotation diameter

1200 mm

190 mm

1250 mm

QF-1000D

SLAM

Navigation

6-8 hrs

Run time

Rated speed

1.8-2 m/s

Position accuracy

± 10 mm

Charging time

≤1.5 hrs

Robot portfolio

QF-1000D

QF-1000D

F4-2000

F4-2000

Q3-600

Q3-600

334 kg

Weight

1640 mm

Rotation diameter

1000 kg

Rated load

1200 mm

190 mm

1250 mm

QF-1000D

SLAM

Navigation

6-8 hrs

Run time

Rated speed

1.8-2 m/s

Position accuracy

± 10 mm

Charging time

≤1.5 hrs

Contact us

No two warehouses are the same – high customization is the key

This portfolio shows only a fraction of what’s available; we source, combine, and orchestrate any robot models through Deus RMS to fit your workflows and performance targets

Industries

Designed for diverse warehouse operations

Pallet-to-Person approach, adapted to different industries, order profiles, and operational constraints.

SKU complexity: High

SKU complexity: High

SKU complexity: High

Results

Measurable business impact

Pallet-to-person automation improves throughput, space utilisation, and cost predictability by eliminating manual pallet movement and forklift-driven bottlenecks.

Performance impact

Up to 400%

Higher storage density

Up to 400%

Higher storage density

Up to 400%

Higher storage density

4-5 times

Higher picking efficiency. More orders processed with the same workforce

4-5 times

Higher picking efficiency. More orders processed with the same workforce

4-5 times

Higher picking efficiency. More orders processed with the same workforce

Up to 300

Pallet or tote presentations per hour at a single MIX workstation

Up to 300

Pallet or tote presentations per hour at a single MIX workstation

Up to 300

Pallet or tote presentations per hour at a single MIX workstation

200-300%

Overall efficiency gain. Significant productivity uplift versus manual picking

200-300%

Overall efficiency gain. Significant productivity uplift versus manual picking

200-300%

Overall efficiency gain. Significant productivity uplift versus manual picking

Operational impact

Increased picks per operator

Higher picks per hour with less physical strain, allowing teams to focus on value-added tasks instead of walking and handling.

Increased picks per operator

Higher picks per hour with less physical strain, allowing teams to focus on value-added tasks instead of walking and handling.

Increased picks per operator

Higher picks per hour with less physical strain, allowing teams to focus on value-added tasks instead of walking and handling.

Higher space utilization

Dense storage layouts and reduced aisle requirements enable higher throughput without warehouse expansion.

Higher space utilization

Dense storage layouts and reduced aisle requirements enable higher throughput without warehouse expansion.

Higher space utilization

Dense storage layouts and reduced aisle requirements enable higher throughput without warehouse expansion.

Predictable peak performance

Stable output during seasonal peaks and demand spikes, protecting SLAs and outbound schedules

Predictable peak performance

Stable output during seasonal peaks and demand spikes, protecting SLAs and outbound schedules

Predictable peak performance

Stable output during seasonal peaks and demand spikes, protecting SLAs and outbound schedules

Lower operational risk

Reduced reliance on manual coordination and forklifts lowers congestion, safety risks, and scaling friction as volumes grow.

Lower operational risk

Reduced reliance on manual coordination and forklifts lowers congestion, safety risks, and scaling friction as volumes grow.

Lower operational risk

Reduced reliance on manual coordination and forklifts lowers congestion, safety risks, and scaling friction as volumes grow.